-

tel:

+86-13222111178 -

email:

info@ntjugao.com

Common Bending Machine Tools and Accessories: A Comprehensive Technical Guide

Common Bending Machine Tools and Accessories: A Comprehensive Technical Guide

Aug 29, 2025

Bending machines are essential in metal fabrication, enabling precise bending of sheet metal and other materials. To achieve optimal performance, various tools and accessories are used alongside these machines. This document provides an in-depth overview of the most commonly used bending machine tools and accessories, their functions, and best practices for their application.

Essential Bending Machine Tools

1. Press Brake Dies (Tooling Sets)

Press brake dies are critical for forming metal sheets into desired shapes. They consist of:

l Punch (Upper Die): The male component that applies force to the workpiece.

l Die (Lower Die): The female component that shapes the metal.

Common Types of Dies:

l V-Dies: Used for standard bends (e.g., 90° angles).

l Gooseneck Dies: Allow for deep return flanges.

l Acute-Angle Dies: For bends sharper than 90°.

l Hemming Dies: Create folded edges for reinforced seams.

l Radius Dies: For curved bends instead of sharp angles.

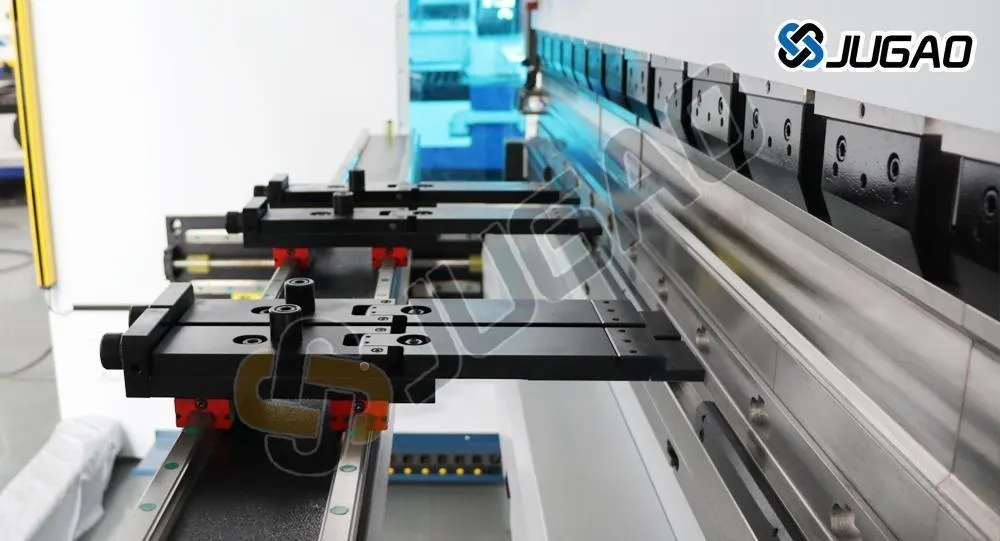

2. Backgauges

Backgauges ensure precise positioning of the workpiece before bending. Modern CNC-controlled backgauges improve accuracy and repeatability.

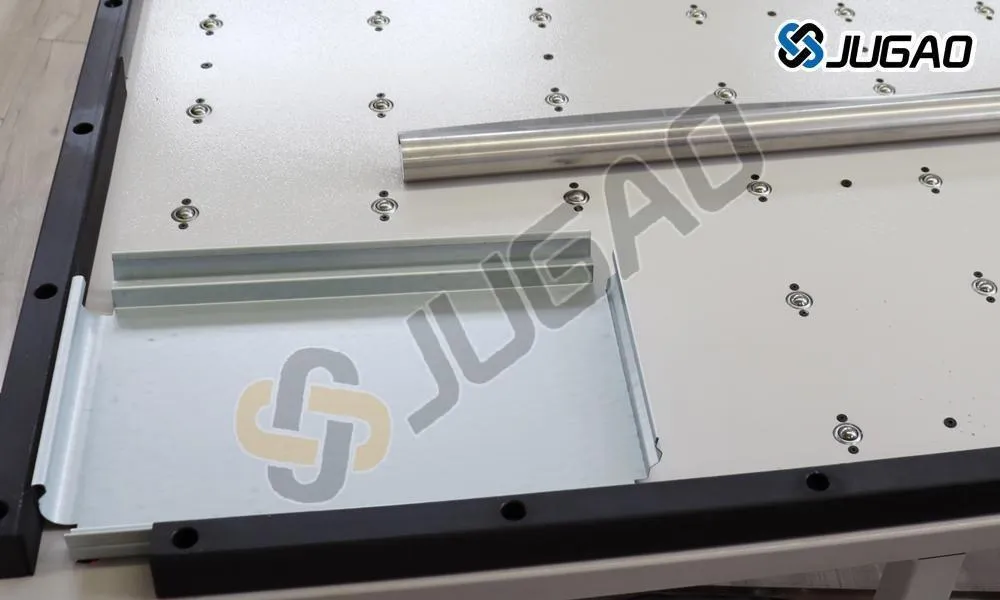

3. Crowning Systems

To compensate for press brake deflection, crowning systems (manual or automatic) adjust the bed to maintain uniform bending force across the length of the workpiece.

4. Tool Holders & Clamps

These secure the punch and die in place, ensuring stability during operation. Quick-change systems allow for faster die swaps.

Key Bending Machine Accessories

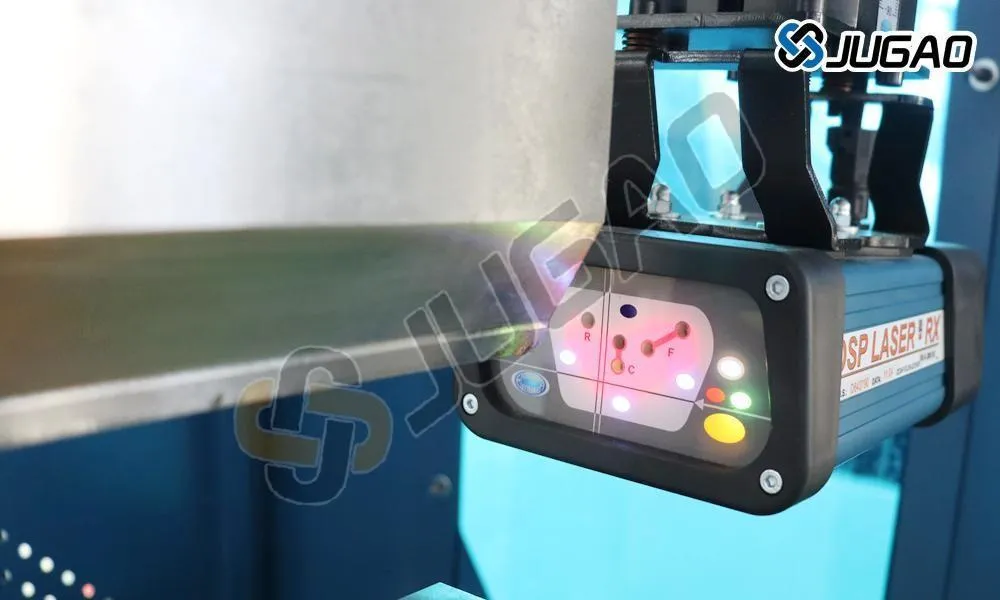

1. Finger Guards & Safety Laser Systems

Prevent operator injuries by detecting hand presence near the bending zone.

2. Angle Measurement Devices

l Digital Protractors: Measure bend angles with high precision.

l Angle Sensors (CNC-integrated): Provide real-time feedback for automated adjustments.

3. Sheet Supports & Lifters

Assist in handling large or heavy sheets, reducing operator fatigue.

4. Hydraulic & CNC Control Systems

l CNC Controllers: Program and automate bending sequences.

l Hydraulic Pressure Systems: Ensure consistent force application

5. Laser or LED Bending Line Projectors

Project a visible guideline onto the workpiece, improving alignment accuracy.

6. Noise Reduction Enclosures

Minimize workplace noise from bending operations.

Selection Criteria for Bending Tools & Accessories

When choosing tools and accessories, consider:

l Material Thickness & Type (steel, aluminum, etc.)

l Bend Angle & Radius Requirements

l Machine Compatibility (tonnage, bed length)

l Production Volume (high-volume vs. custom jobs)

l Automation Needs (CNC vs. manual operation)

Maintenance & Best Practices

l Regular Inspection: Check dies for wear, cracks, or misalignment.

l Proper Lubrication: Reduces friction and prolongs tool life.

l Correct Storage: Organize tools to prevent damage.

l Operator Training: Ensure safe and efficient use of accessories.

Conclusion

The right selection and use of bending machine tools and accessories significantly impact precision, efficiency, and safety in metal fabrication. By understanding the different types of dies, gauges, and supporting systems, manufacturers can optimize their bending operations for superior results.

Recent Posts

October 26, 2016

The Most Successful Engineering Contractor

Oct 29, 2025

Key Configuration Steps for the DELEM DA-66T Tool

Oct 24, 2025

Key Insights from the ESTUN E21 Operation Guide

Oct 24, 2025

Types of Metal Bending Processes