-

tel:

+86-13222111178 -

email:

info@ntjugao.com

Performance Analysis of Laser Cutting and Engraving

Performance Analysis of Laser Cutting and Engraving

Aug 28, 2025

Laser cutting and engraving technologies are widely used in industrial manufacturing, artistic creation, and electronics due to their high precision, efficiency, and non-contact processing capabilities. This document provides a detailed analysis of the principles, performance metrics, influencing factors, applications, and future trends of laser cutting and engraving.

Fundamental Principles

1. Laser Cutting

Laser cutting utilizes a high-energy-density laser beam to melt, vaporize, or ignite materials, while an assist gas (e.g., oxygen, nitrogen) blows away molten residues, enabling precise material separation.

Laser engraving involves localized ablation or chemical reactions on a material’s surface to create permanent marks or patterns. Unlike cutting, engraving typically does not penetrate the material but modifies its surface texture or color.

Performance Metrics

1. Precision

l Positioning Accuracy: Typically ±0.01 mm, with high-end systems achieving ±0.005 mm.

l Repeatability: Generally within ±0.02 mm for consistent batch processing.

l Minimum Line Width: Depends on laser spot size (10–100 µm); ultrafast lasers enable micron-scale engraving.

2. Processing Speed

l Cutting Speed: Depends on material thickness and laser power (e.g., CO₂ lasers cut 1 mm stainless steel at 20 m/min).

l Engraving Speed: Vector engraving can reach 1000 mm/s, while raster engraving is slower due to scanning methods.

3. Material Compatibility

|

Material |

Laser Type |

Performance |

|

Metals (Stainless steel, Al, Cu) |

Fiber laser, High-power CO₂ |

High-precision cuts, oxidation-assisted engraving |

|

Non-Metals (Wood, Acrylic, Leather) |

CO₂ laser (10.6 µm) |

Smooth cuts, detailed engraving |

|

Composites (PCB, Carbon Fiber) |

UV laser (355 nm) |

Minimal heat-affected zone (HAZ), high-resolution engraving |

4. Surface Quality

l Cut Edge Roughness: Typically Ra < 10 µm (fiber lasers achieve Ra < 5 µm for metals).

l Engraving Depth Control: Adjustable via power and passes (±0.01 mm precision).

Key Influencing Factors

1. Laser Parameters

l Wavelength: UV (355 nm) for fine engraving; CO₂ (10.6 µm) for non-metals.

l Power: Higher power increases speed but may cause thermal distortion.

l Pulse Frequency (Pulsed Lasers): Affects efficiency and HAZ.

2. Optical System

l Focus Lens: Focal length determines spot size and depth of field (short focal lengths enhance precision).

l Beam Quality (M²): Near-diffraction-limited beams (M² ≈ 1) yield smoother cuts.

3. Process Optimization

l Assist Gas: Oxygen boosts speed (but oxidizes edges); nitrogen ensures clean cuts.

l Scanning Strategy: Raster for large-area engraving; vector for contours.

Applications

1. Industrial Manufacturing

l Sheet Metal Fabrication: Automotive/aerospace component cutting.

l Electronics: FPC (Flexible PCB) cutting, PCB micro-drilling.

2. Creative & Customization

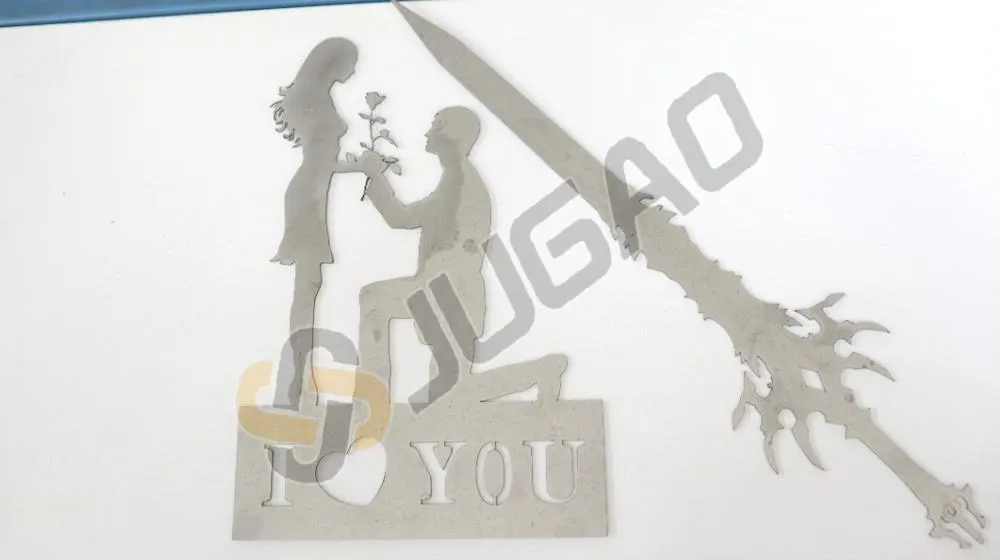

l Artwork: Wood/acrylic engravings, leather branding.

l 3D Relief: Grayscale engraving for depth effects.

3. Medical & Research

l Surgical Tools: Precision-cut stainless steel instruments.

l Microprocessing: Ultrafast (femtosecond/picosecond) lasers for microstructures.

Future Trends

1. Higher Power & Efficiency: Multi-beam processing for increased throughput.

2. Smart Automation: AI-driven parameter optimization.

3. Green Lasers: Energy-efficient fiber lasers.

4. Ultrafast Laser Adoption: Expansion in medical and semiconductor fields.

Conclusion

Laser cutting and engraving offer unmatched precision and versatility, making them indispensable in modern manufacturing. Advances in laser sources, automation, and process control will further enhance their capabilities and applications.

Recent Posts

October 26, 2016

The Most Successful Engineering Contractor

Dec 03, 2025

Factors affecting laser cutting speed and efficiency

Nov 25, 2025

Comparison of IPG and Raycus lasers

Nov 12, 2025

Fiber Laser Cutting Machine Operation Guide