-

tel:

+86-13222111178 -

email:

info@ntjugao.com

Laser welding speed, laser power and material thickness

Laser welding speed, laser power and material thickness

Nov 17, 2025

The relationship between laser welding speed, power, and material thickness is crucial for determining the quality and efficiency of welding processes. These three factors (welding speed, laser power, and material thickness) are interdependent and must be optimized to achieve strong, defect-free welds. Understanding how they interact is vital for industries like automotive, aerospace, and manufacturing, where precision and material integrity are paramount.

Basic introduction of laser welding machine

Laser welding machine uses high energy laser pulse to local heating of the material in a small area, through heat conduction to melt the material, to achieve welding. Its working principle mainly involves the following aspects:

l Optical focus: The laser welding machine uses the laser beam produced by the laser, through lenses or mirrors and other optical components, to focus the laser energy on the welding point.

l Heat conduction: When the laser beam is irradiated on the surface of the workpiece, the laser energy is absorbed and converted into heat energy. The heat energy is gradually transferred along the metal conductive part of the welding joint through heat conduction, making its temperature rise.

l Melting and mixing: When the metal surface is exposed to a high enough temperature, the metal begins to melt and form a molten pool. Under the action of the laser beam, the molten pool spreads and mixes rapidly to achieve the connection of the metal joint.

l Cooling and solidification: After the laser beam is stopped, the molten pool gradually cools and forms a welded joint during the solidification process. During the solidification process, metal molecules rearrange and crystallize to form a strong welded connection.

Advantages of laser welding machine

l High precision: can achieve micron-level welding accuracy, especially suitable for the welding requirements of miniature and complex structures.

l Fast speed: Especially in the deep melting welding mode, due to the concentration of laser energy, the pool is small and deep, resulting in fast welding speed and high production efficiency.

l Small deformation: Compared with traditional welding methods, laser welding has lower heat input and less influence on the surrounding material, which is conducive to reducing the deformation after welding.

l Small thermal affected zone: can reduce the thermal damage to surrounding materials and improve the quality of welded joints.

Laser welding power, speed and material thickness

1. Laser welding power supply

Laser power is the decisive factor in determining weld penetration depth and total energy input during welding. It determines the heat required to melt base materials and form a welding pool. For thicker plates, higher laser power is typically needed to achieve sufficient penetration depth, while thinner materials can be protected from excessive melting or burn-through with lower power settings.

l Higher power: can achieve deeper penetration, suitable for welding thicker materials. However, if the power on the thin plate is too high, it will lead to small hole instability, spatter and even burn through defects.

l Reduced power consumption: More suitable for thinner plates, providing better control and preventing overheating from causing material deformation or melting.

The laser power must be carefully selected according to the thickness of the material to ensure proper fusion and no defects.

2. Welding speed

Welding speed refers to the rate at which a laser travels along a welded joint. It affects heat input per unit length and is a key factor in determining welding quality. There is a direct relationship between welding speed and laser power, as increasing one typically requires adjusting the other to maintain desired welding performance.

l Higher welding speed: Reduces heat input per unit length of welding, which is beneficial for thin materials and avoids overheating and deformation. However, if the speed is too high for a given power, the weld may lack penetration, resulting in weak joints or incomplete fusion.

l Reduce welding speed: Increase heat input to melt more and penetrate deeper into the substrate. This is advantageous for thicker plates, but can cause overheating of thin materials or excessive flow of molten metal.

Using the best welding speed is critical to balance heat input and avoid common welding defects (such as porosity, cracking or deformation).

3. Material thickness

The thickness of welding materials plays a crucial role in determining required power and permissible welding speeds. Thicker plates require more heat to achieve full penetration, which means the laser must operate at higher power levels and may need to reduce the welding speed to allow sufficient time for heat absorption. Conversely, thinner plates demand less power and higher speeds to prevent excessive heat input that could lead to melting or burn-through.

l Thicker plates: More energy is required to achieve full penetration. The laser must provide higher power and the welding speed must be slower to transfer enough energy to the material.

l Thinner plates: Less energy is required, so the laser power can be reduced and the welding speed increased. Thin materials are more prone to heat-related deformation, so precise control of these variables is critical.

The interaction between force, speed and thickness

The relationship between laser welding speed, power and sheet thickness is a balancing act. For each thickness of material, there is an optimal combination of laser power and welding speed to ensure high welding quality, correct penetration depth and minimal defects.

For example, when welding thick steel plates, increasing laser power without adjusting the welding speed may result in excessive heat input, leading to defects such as warping or overly wide weld beads. Conversely, reducing the welding speed without boosting power could cause welds to become too deep, potentially causing material overheating. For thin materials, excessive power combined with slow welding speed might lead to over-melting or burn-through of the material.

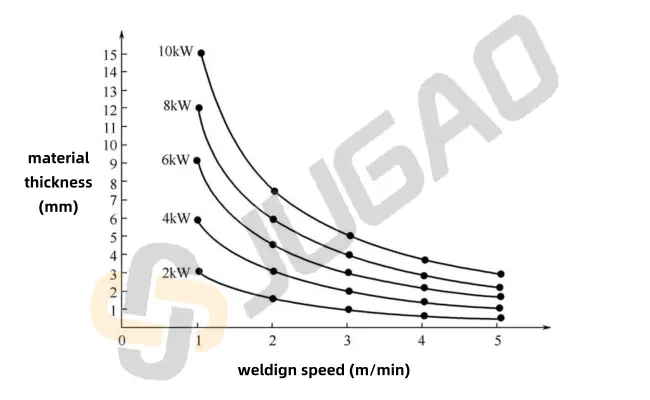

Relationship between laser welding speed and plate thickness

Thick plates require a slower welding speed

When laser welding thicker plates, the material requires more heat to achieve complete penetration and ensure adequate joint strength. Therefore, it's crucial to reduce the welding speed to allow sufficient time for the laser beam to transfer heat throughout the entire thickness of the material. If the welding speed is too fast, the laser energy won't penetrate fully, which may result in insufficient penetration depth, discontinuous welds, or inadequate joint strength.

l Thick plate (>6mm): The welding speed should be slow to ensure that the laser energy can fully penetrate the entire thickness of the plate to form a stable and high strength weld.

Thin plates can be welded faster

Compared to thick plates, thin sheet materials (less than 2mm) require less heat, allowing lasers to penetrate the entire thickness more easily. This enables faster welding speeds that effectively prevent overheating or excessive melting, thus avoiding welding deformation or burn-through. Additionally, higher welding speeds can significantly improve overall efficiency.

l Thin plate (<2mm): the welding speed should be fast to reduce the deformation, burn through and other welding defects caused by material overheating.

Effect of laser power on welding speed and plate thickness

Laser power determines the energy input during welding. High-power lasers deliver stronger heat output, making them ideal for welding thicker materials, while low-power lasers are better suited for thin plates. When selecting welding speed, it's crucial to match the laser power with the plate thickness to ensure adequate penetration without causing material overheating.

Thick plate high power laser welding

When welding thicker plates, higher laser power is required to ensure sufficient heat transfer into the material to form a stable molten pool. Combined with a lower welding speed, the laser energy can heat the material uniformly over a longer period of time to ensure the depth of fusion.

l 6kW power welding thick plate (10mm): welding speed is usually between 0.5-1.2m/min.

Thin plate low power laser welding

In thin plate welding, lower power and faster speeds help prevent overheating and weld deformation. Typically, when the laser power is in the 2-3kW range, plates less than 2mm thick can be processed.

l 2kW power welding thin plate (1mm): welding speed is usually between 5-10m/min.

Laser welding machine power and speed comparison table

The following is a comparison of laser welding machine power and welding speed under different plate thickness conditions:

|

Material thickness (mm) |

Laser power (kW) |

Welding speed (m/min) |

|

1.0 |

2.0 |

7.0 |

|

2.0 |

3.0 |

4.5 |

|

4.0 |

4.0 |

2.5 |

|

6.0 |

6.0 |

1.2 |

|

8.0 |

8.0 |

0.8 |

|

10.0 |

10.0 |

0.6 |

l Thin plate (1-2mm): The combination of low power (2-3kW) and high welding speed (5-10 m/min) is suitable for this type of welding, ensuring fast operation without excessive heat generation.

l Medium and thick plate (4-6mm): medium power (4-6kW) combined with medium speed welding (1-3 m/min) can ensure the depth of fusion and avoid excessive heat affected zone.

l Thick plates (>6mm): For thick plates, use high power (8-10kW) combined with slow welding (0.5-1 m/min) to ensure that sufficient heat penetrates into the material and forms a high strength joint.

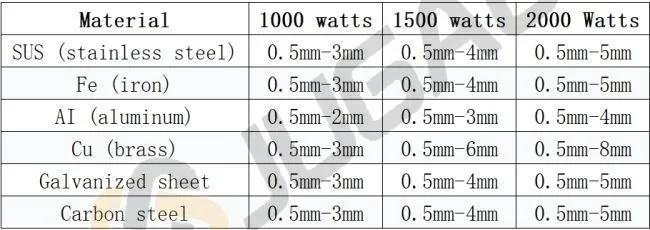

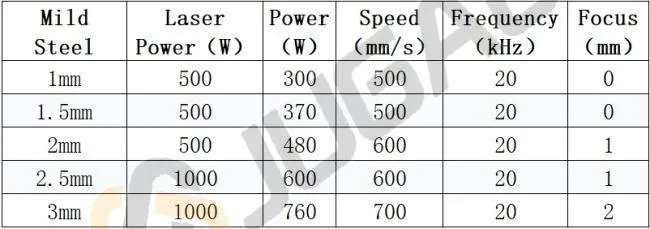

Laser welding power, thickness and speed chart

Laser welding is a precision joining technology that delivers high-speed, high-quality welding for various metal thicknesses. The relationship between laser power, material thickness, and welding speed is critical to achieving optimal results. This is a comprehensive chart detailing these parameters for common materials.

Mild steel

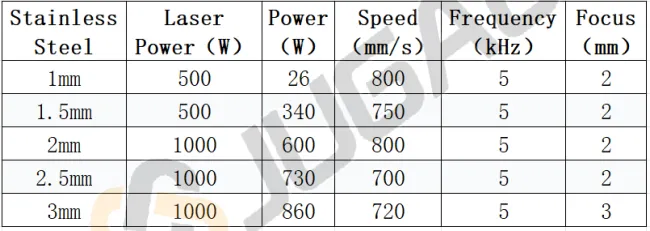

Stainless steel

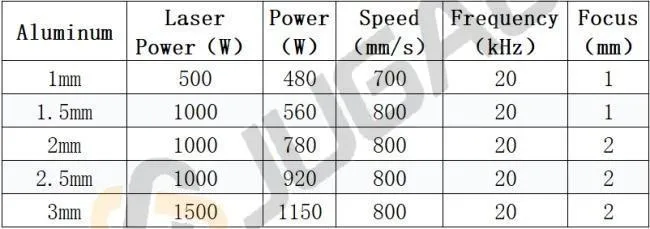

Aluminium

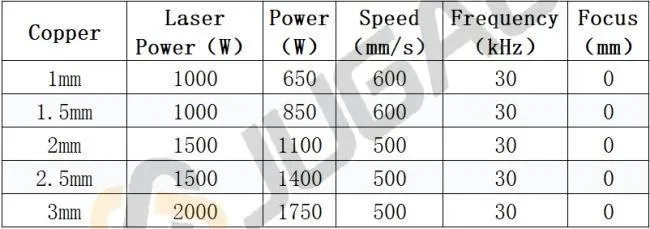

Copper

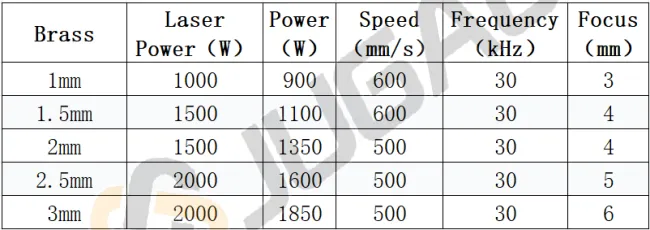

Yellow metal

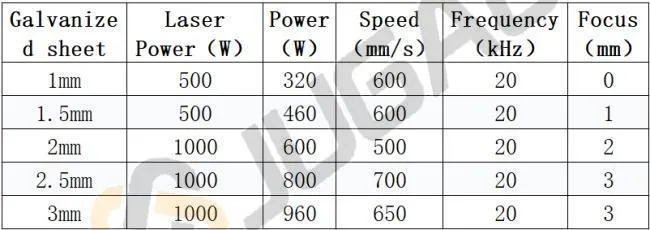

Galvanized sheet

Conclusion

In summary, thicker plates generally require higher power and slower welding speeds, while thinner materials need lower power and faster welding speeds. This delicate balance ensures efficient energy utilization and superior welding quality. Understanding these interrelationships enables manufacturers to optimize their processes for specific applications, materials, and thicknesses, resulting in stronger, more reliable welds with fewer defects.

Recent Posts

October 26, 2016

The Most Successful Engineering Contractor