-

tel:

+86-13222111178 -

email:

info@ntjugao.com

ESTUN E21 Alarm Troubleshooting: A Step-by-Step Guide

ESTUN E21 Alarm Troubleshooting: A Step-by-Step Guide

Feb 03, 2026

Effective troubleshooting of the ESTUN E21 alarm system is essential for maintaining uninterrupted press brake operations. If you are facing challenges with your ESTUN E21 controls and looking for reliable solutions, this guide provides clear and actionable steps to diagnose and resolve common alarm conditions. Whether you're dealing with unexpected error codes or system irregularities, the following information will help you rapidly identify issues and implement solutions—reducing downtime and sustaining operational performance.

Understanding ESTUN E21 Alarm System

The ESTUN E21 control system is engineered to improve machining precision and productivity. A central component of its design is the automatic detection of internal or external irregularities, which triggers real-time alert messages displayed in the system’s alarm list.

Step 1:

On programming management page, press![]() to enter programming constant page.

to enter programming constant page.

Step 2:

On programming constant page, press the right arrow key to enter “Alarm history” page to view all alarm history.

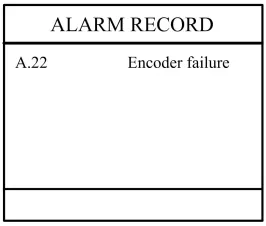

As shown in Figure, the latest 6 alarms, alarm number and causes can be viewed on this page.

Steps for Efficient ESTUN E21 Alarm Troubleshooting

Step 1: Identifying the Alarm Message

Begin by carefully reviewing the alarm message displayed on the control unit. Each message correlates to a specific issue, providing a starting point for ESTUN E21 Alarm Troubleshooting.

Step 2: Checking for Mechanical Obstructions

Inspect the machine for any physical obstructions or debris that may hinder movement. This is a common cause of alarms related to mechanical failure.

Step 3: Inspecting Electrical Components

Ensure all electrical connections are secure and free of damage. Check circuit boards, fuses, and other electrical components for signs of wear or failure. Proper examination of these components is crucial in the process of ESTUN E21 Alarm Troubleshooting.

Step 4: Consulting the Alarm List

Refer to the device’s alarm list for detailed information about specific error codes and recommended actions. This list is integral in directing the troubleshooting process efficiently.

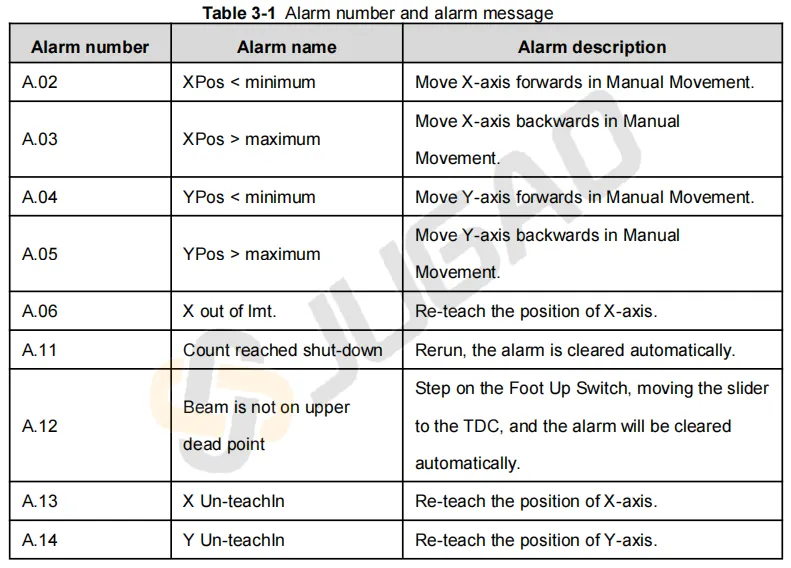

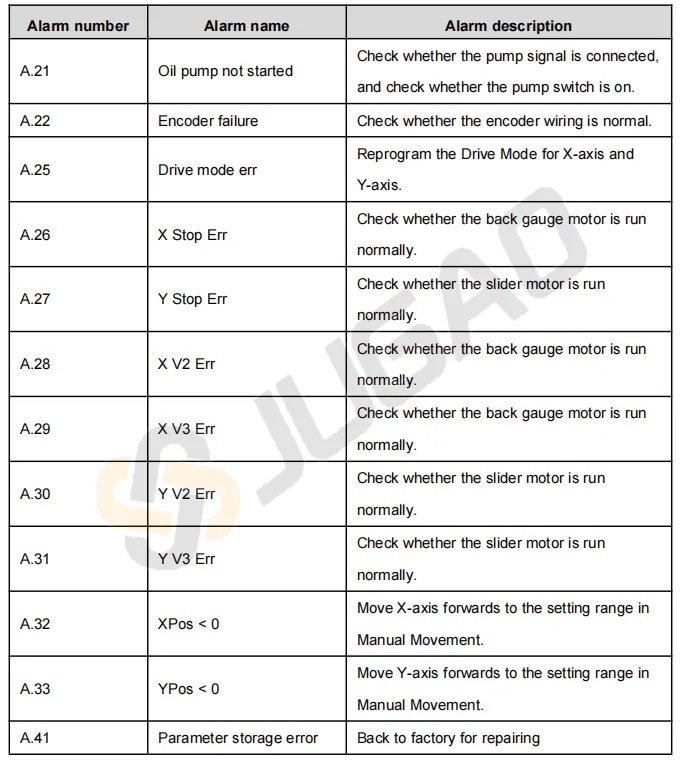

Alarm history and message is shown in Table 3-1.

Preventive Measures for Avoiding Alarms

To prevent frequent alarms and ensure the longevity and efficiency of your ESTUN E21 system, effective ESTUN E21 Alarm Troubleshooting is vital. Alongside troubleshooting, regular maintenance and careful operation are essential. Implementing these preventive measures will reduce downtime and improve machine reliability.

Routine Inspections

Conducting comprehensive routine inspections is vital for maintaining the health of your machine. Here are the key areas to focus on:

l Electrical Components: Regularly inspect all wiring, connections, and circuit boards for signs of wear or damage. Replace any frayed wires and secure loose connections to prevent electrical faults.

l Mechanical Parts: Check for wear and tear in moving components, such as gears and bearings. Lubricate these parts as necessary to ensure smooth operation and reduce the risk of mechanical failure.

l Calibration: Regularly verify and adjust the calibration settings of your ESTUN E21 to maintain accuracy and precision in operations. This helps prevent operational errors that may trigger alarms.

l Documentation: Keep a detailed log of inspection dates, findings, and maintenance work performed. This documentation will help track the machine’s condition over time and anticipate potential issues.

Managing Machine Load

Proper management of machine load is crucial to avoid overload conditions, which can lead to frequent alarms and permanent damage:

l Know Your Limits: Understand and adhere to the manufacturer’s specified load capacities for your machine. Overloading the machine can lead to mechanical stress and failure.

l Balanced Operations: Distribute workload evenly across shifts to prevent continuous strain on the machine. This not only avoids overloading but also extends the machine’s operational life.

l Monitor Performance: Regularly monitor the machine’s performance indicators for signs of stress, such as unusual noises or vibrations. Adjust operations accordingly.

l Training: Ensure all operators are adequately trained on the machine’s capacity limits and the importance of maintaining them. Training should include recognizing signs of overload and appropriate corrective measures to prevent situations that necessitate ESTUN E21 Alarm Troubleshooting..

By incorporating these preventive measures into your regular maintenance routine, you can effectively minimize the occurrence of alarms and enhance the performance and productivity of your ESTUN E21 system.

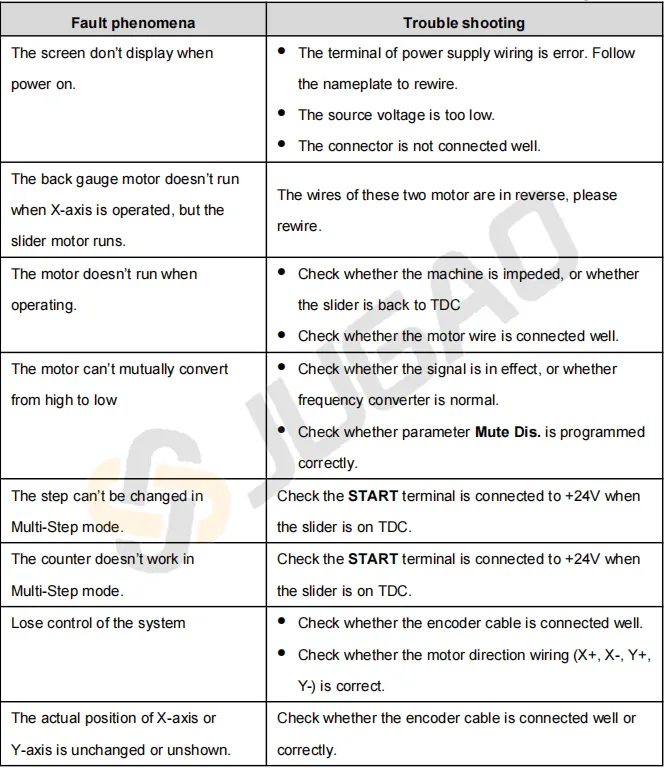

Common Faults and Troubleshooting

Following these steps and implementing preventive measures will help you efficiently resolve ESTUN E21 alarms, ensuring your machinery operates smoothly and effectively.

Conclusion

Effective troubleshooting of ESTUN E21 alarms requires a structured methodology. Key steps include accurately interpreting alarm messages, inspecting for mechanical blockages, verifying electrical connections, and systematically reviewing the alarm history. Establishing regular preventive maintenance schedules and ensuring proper machine loading can proactively mitigate many frequent alarm conditions.

Adhering to these procedures will substantially minimize operational interruptions and help sustain peak machine performance. For specialized technical support or more in-depth guidance, our expert team remains available to assist. We also recommend exploring our extended library of technical documentation for additional operational insights and best practices to further optimize your ESTUN system performance.

Recent Posts

October 26, 2016

The Most Successful Engineering Contractor

Jan 30, 2026

Sheet Metal Fabrication Technology