-

tel:

+86-13222111178 -

email:

info@ntjugao.com

Key Insights from the ESTUN E21 Operation Guide

Key Insights from the ESTUN E21 Operation Guide

Oct 24, 2025

To boost the efficiency of your metal fabrication workflows, grasping the essentials of the ESTUN E21 Operation Guide is vital. If you’re seeking professional advice to optimize the use of this controller, you’ve come to the right place.

This article will highlight core insights from the ESTUN E21 Operation Guide, offering practical tips to streamline your operational processes. Whether you’re an experienced operator or new to this system, these insights will equip you with the necessary knowledge to enhance precision and productivity in your tasks. Let’s explore the guide and unlock the full potential of the ESTUN E21 for your machinery.

Basic Operation Procedure

To use the ESTUN E21 controller efficiently, you first need to familiarize yourself with its basic operation process. Begin by verifying that the controller is properly connected and powered on. Once the machine is activated, the first step is to enter the required operational parameters on the controller display. This includes choosing the operation mode (manual or automatic) according to the specific task needs. Following these initial steps ensures you’re set up for precise operation, in line with the guidance provided in the ESTUN E21 Operation Guide.

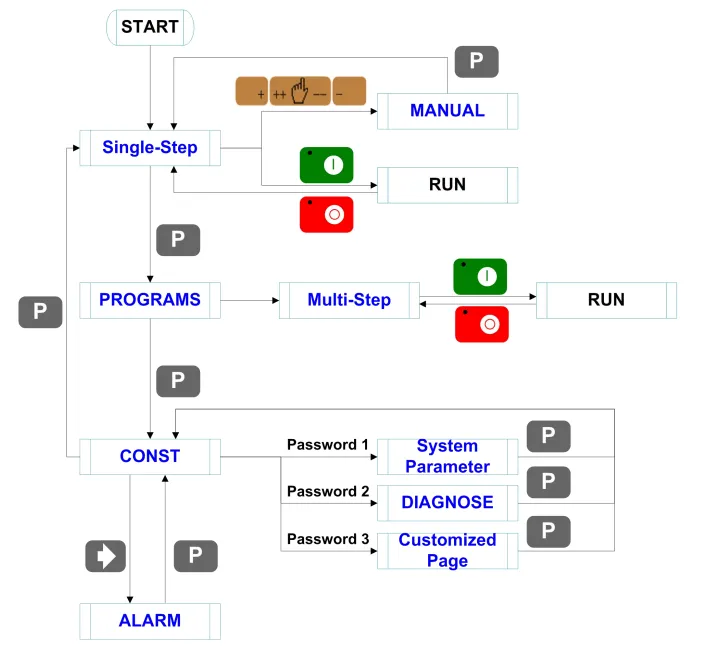

The basic mode switching and operation process of the device is displayed in the figure.

Programming the ESTUN E21 Controller

Programming your press brake with the ESTUN E21 is simple yet effective. To program a task, first access the programming menu on the controller. This involves navigating the interface to enter commands such as bend angles, material type, and material thickness. By following these steps, you can ensure the machine operates with the precision needed for complex tasks, as specified in the ESTUN E21 Operation Guide. You can also adjust and save multiple programs, allowing for flexibility and efficiency in daily operations.

The device offers two programming methods: single-step programming and multi-step programming. Users can select the appropriate method based on actual work requirements.

Single-step Programming

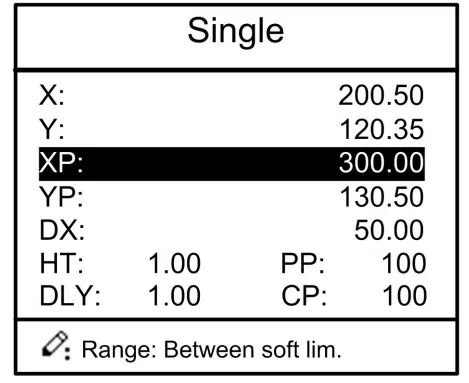

Single-step programming is typically employed for completing workpiece processing in a single operational step. When the controller is powered on, it automatically navigates to the single-step program page.

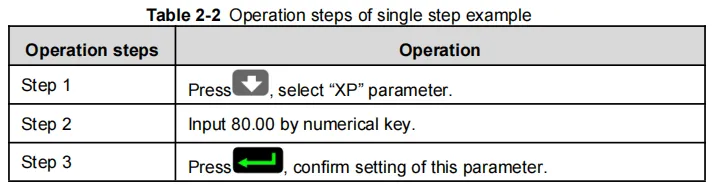

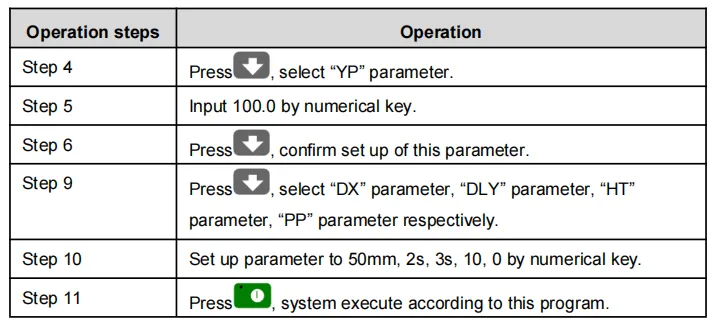

Operation Steps

1. After the device starts up, it will automatically enter the single-step program configuration page.

2. Press the designated key to select the parameter that requires configuration, use the numeric keys to enter the program value, and then press the confirmation key to finalize the entry.

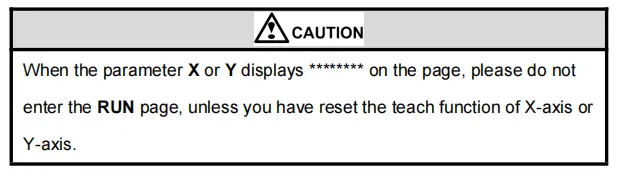

Note: Parameters can only be configured when the Stop indicator is lit.

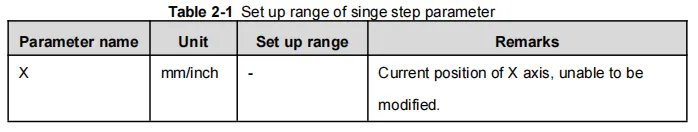

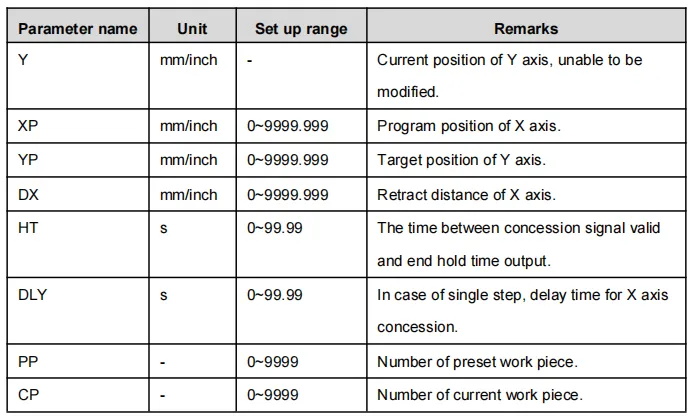

The configuration range for single-step parameters is shown in the table.

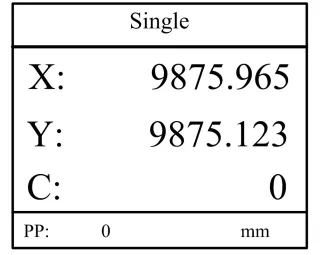

3. Press the start key

and the system will run according to this program, as shown in the figure.

Operation Example

As recommended in the ESTUN E21 Operation Guide, you can enhance your single-step program by configuring the bending depth to 100.0mm and the back gauge to 80.00mm. Set the retract distance to 50mm, with a concession waiting time of 2 seconds and a holding time of 3 seconds. Assign the workpiece number as 10, ensuring each operational step aligns with the details provided in the guide’s table. Following these settings guarantees efficient and accurate metal fabrication results.

Multi-step Programming

Multi-step programming is designed for processing a single workpiece through multiple distinct operational steps. It enables the continuous execution of multiple steps, thereby improving processing efficiency.

Operation Steps

1. When the device is powered on, it automatically displays the single-step parameter page.

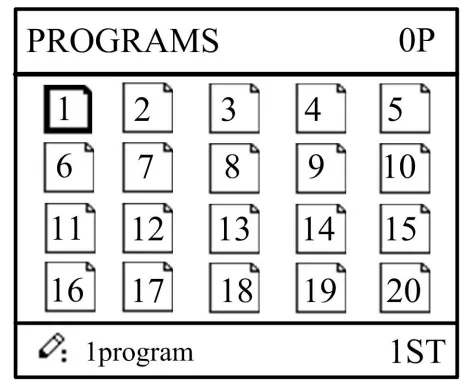

2. Press the mode key to navigate to the program management page, as shown in the figure.

3. Press the selection key to choose a program serial number, or enter a program number directly (e.g., enter “1”).

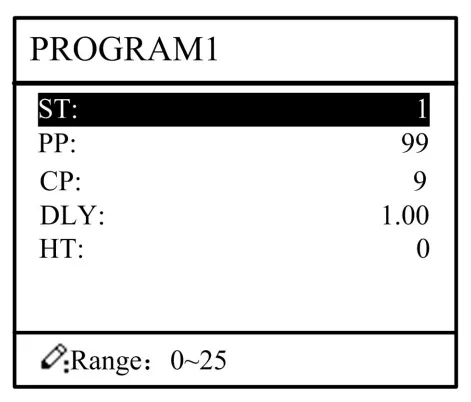

4. Press the confirm key to access the multi-step program configuration page, as shown in the figure.

5. Press the Down arrow key to select the multi-step programming parameter that needs configuration, enter the desired value, and press the Enter key to activate the setting.

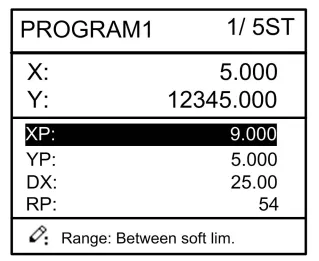

6. After completing the configuration, press the Right arrow key to enter the step parameter configuration page, as shown in the figure.

7. Press the Down arrow key to select the step parameter requiring configuration, enter the program value, and press the Enter key to confirm the setting.

8. Use the Left and Right arrow keys to switch between steps. If you’re on the first step, pressing the Left arrow key will take you to the last page of step parameter configuration; if you’re on the last step, pressing the Right arrow key will return you to the first page of step parameter configuration.

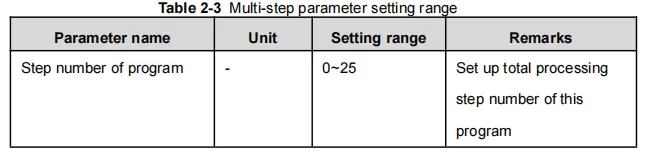

The configuration range for multi-step parameters is shown in the table.

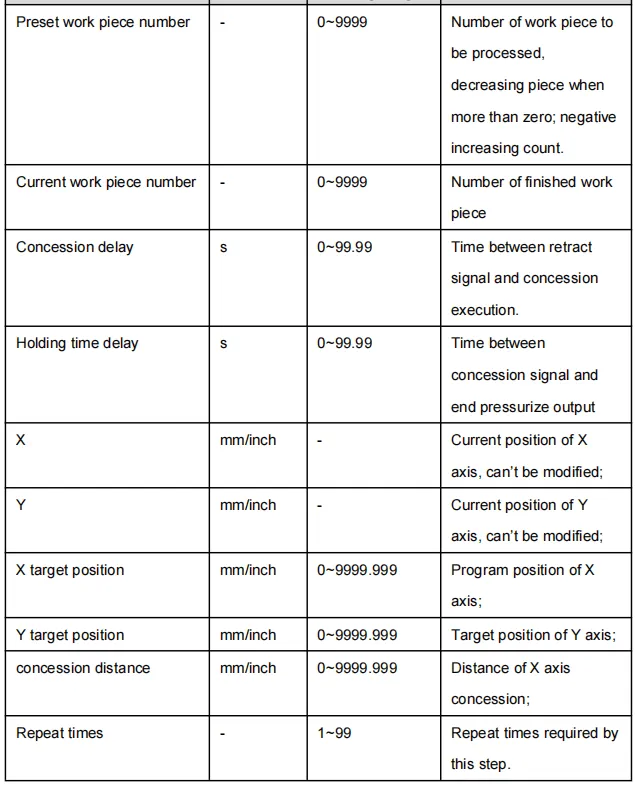

9. Press the start key, and the system will operate according to this program, as shown in the figure.

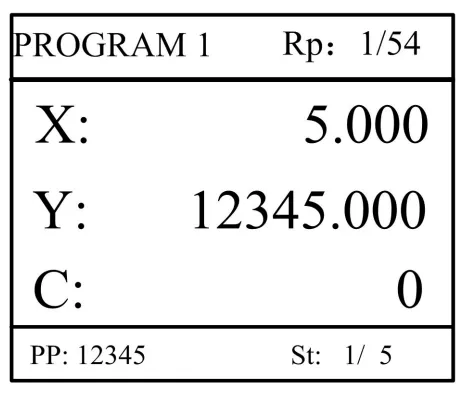

Operation Example

Background: As illustrated below, 50 units of a single workpiece need to be processed, with the following requirements:

• First bend: 50mm

• Second bend: 100mm

• Third bend: 300mm in the opposite direction

Analysis: Based on the workpiece specifications and machine technical conditions:

• First bend: Set the X-axis position to 50.0mm, Y-axis position to 85.00mm, and concession to 50mm.

• Second bend: Set the X-axis position to 100.0mm, Y-axis position to 85.00mm, and concession to 50mm.

• Third bend: Set the X-axis position to 300.0mm, Y-axis position to 85.00mm, and concession to 50mm.

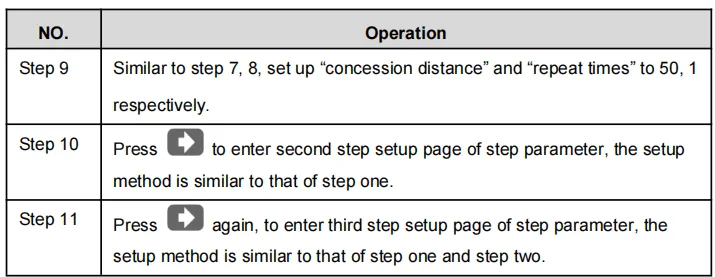

Edit the processing program for this workpiece in Program No. 2. The specific operation process is shown in the table.

When using the ESTUN E21 Operation Guide, efficient multi-step programming relies on the following key points:

• Return to the starting step: After finishing multi-step programming, always return to the initial step to ensure the program runs in the correct sequence.

• Parameter navigation: Use the Left and Right arrow keys to browse and modify all step parameters effectively.

• Program adjustments: Programs can be edited and revised as needed, ensuring flexibility and adaptability.

• Automated processing: After completing a batch (e.g., 50 workpieces), the system stops automatically. You can restart it to process the next batch smoothly.

Following these steps—guided by the ESTUN E21 Operation Guide—ensures optimal machine performance and productivity.

Parameter Setting

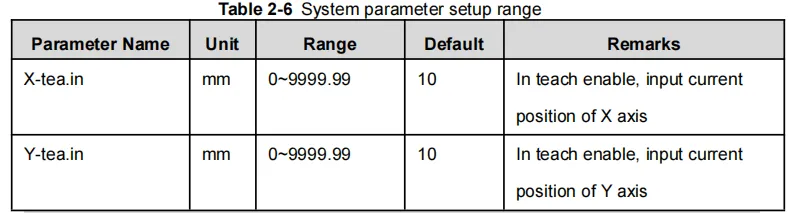

Users can configure all parameters necessary for the system’s normal operation, including system parameters, X-axis parameters, and Y-axis parameters.

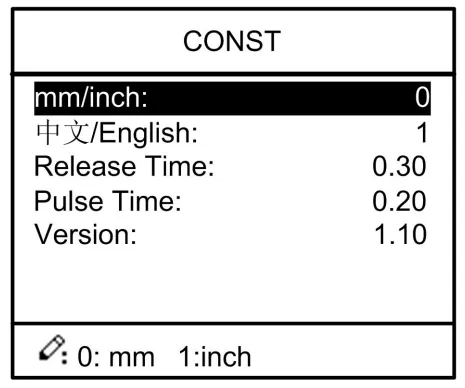

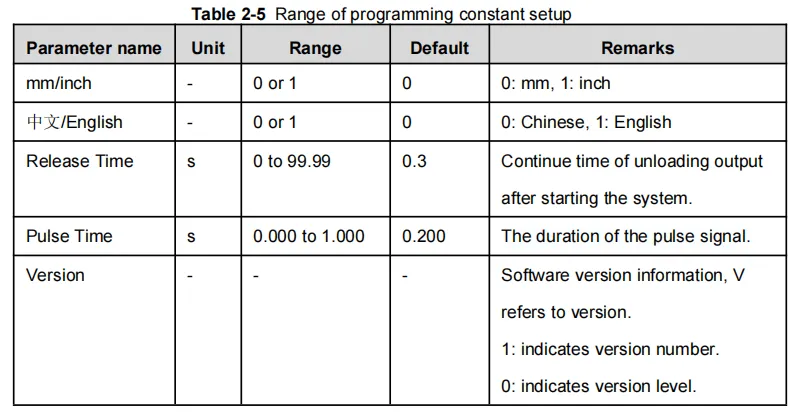

1. On the program management page, press the P key to access the programming constant page (as shown in the figure). You can configure programming constants on this page.

The configuration range for programming constants is shown in the table.

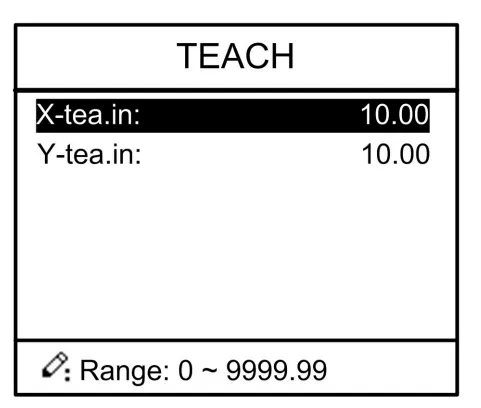

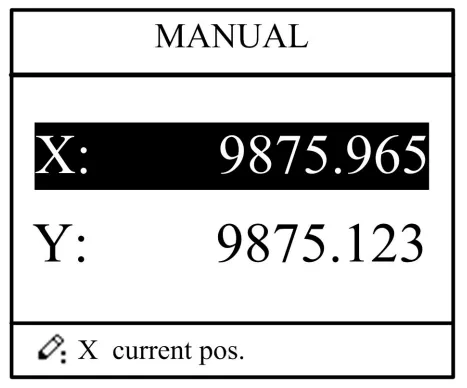

2. Enter the password “1212” and press the Enter key to open the Teach Page (as shown in the figure). Configure the parameters here, and the parameter configuration range is shown in the table.

How to Teach: The ESTUN E21 Operation Guide recommends measuring the slider and back gauge positions to ensure precision. If direct measurement is challenging, program a process and then measure the finished workpiece. This method guarantees accuracy and aligns with the guide’s strategies for optimal machine performance.

3. Press the P key to return to the programming constant page.

Manual Adjustment

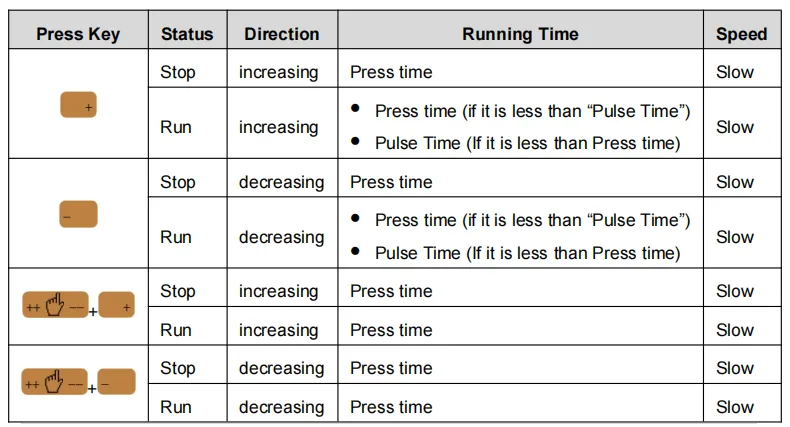

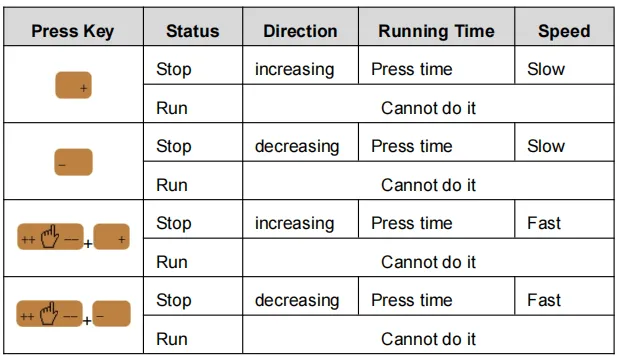

In single-step mode, you can manually control axis movement by pressing the corresponding keys. This approach assists users in adjusting the machine tool and workpiece.

1. On the single-step parameter configuration page, press the Plus or Minus key to switch to the manual page (as shown in the figure).

2. Adjust the axis position according to your actual needs, following the specifications in the table above:

◦ If the drive mode of the corresponding axis is a common motor: [Follow the specific operation details in the original guide’s table]

Note: When the system is in running status, manual adjustment only works for the X-axis.

◦ If the drive mode of the corresponding axis is frequency-controlled: [Follow the specific operation details in the original guide’s table]

1. Press the P key to return to the single-step parameter configuration page.

Frequently Asked Questions (FAQ)

How does the ESTUN E21 Operation Guide help improve machine precision?

The guide offers detailed guidance on calibration and alignment processes—steps that are critical for achieving precise operations. Consistently following these guidelines can greatly improve the machine’s accuracy and overall performance.

What troubleshooting steps are outlined in the ESTUN E21 Operation Guide?

The ESTUN E21 Operation Guide outlines several troubleshooting measures, such as inspecting electrical connections, checking error codes shown on the display, and referring to the manual for resolving specific errors.

Conclusion

In summary, the ESTUN E21 Operation Guide delivers key insights for the efficient operation of your equipment. Key points to remember include mastering the basic operation process, comprehending single-step programming, and proficiently managing multi-step programming. This guide ensures operators have the foundational knowledge needed to enhance machine performance and productivity.

Correct setup and regular maintenance are critical for extending the service life and maintaining the performance of your press brake. By following these guidelines and conducting routine maintenance, you can reduce downtime and boost production efficiency. For more detailed support or additional questions, feel free to contact our team. Additionally, you can explore other related documents in our documentation section to gain further information.

Recent Posts

October 26, 2016

The Most Successful Engineering Contractor

Nov 05, 2025

How to choose the best plate rolling machine?

Oct 29, 2025

Key Configuration Steps for the DELEM DA-66T Tool