-

tel:

+86-13222111178 -

email:

info@ntjugao.com

Debugging of folding machine

Debugging of folding machine

Jul 29, 2024

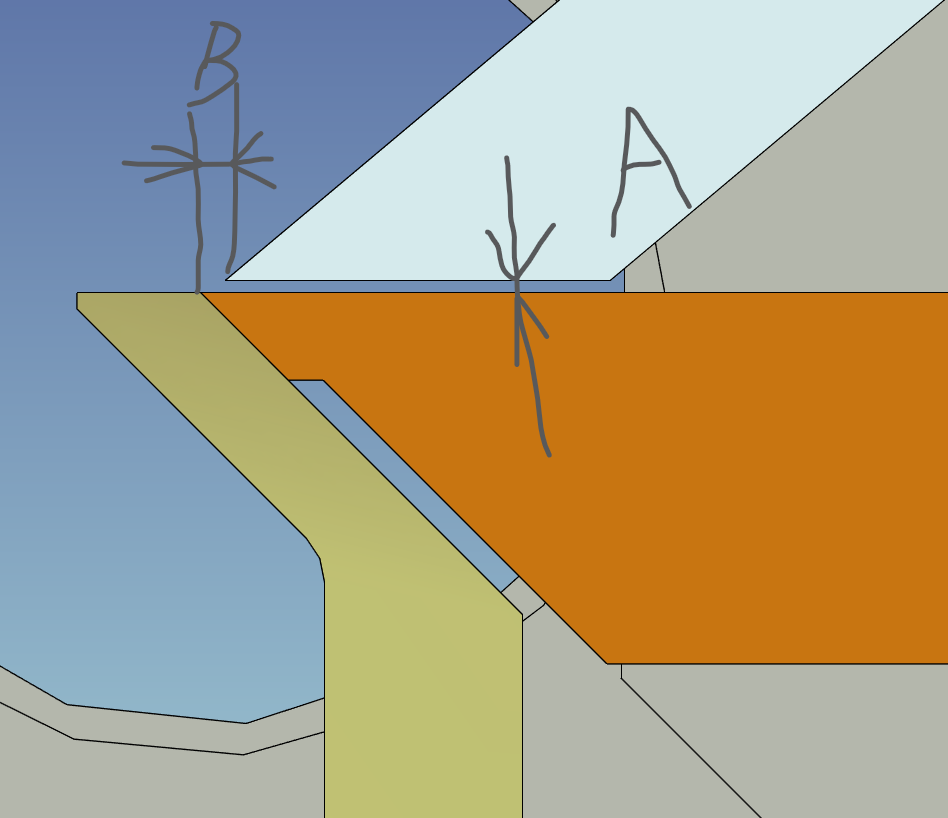

1.Adjustment of bending gap

As shown in the picture B is the bending gap. Generally choose B=2*t (plate thickness) , by adjusting the eccentric axis in the below picture , the compression beam must be loosened and it needs to be adjusted when the compression is loosened; both ends must be adjustment.

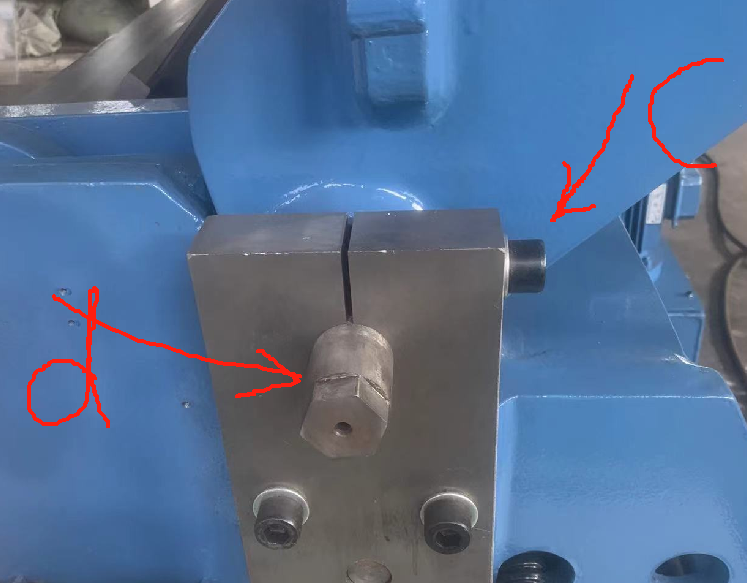

a)Loosen screw C,

b)Adjust the eccentric shaft d

c)Measure the size of B

d)Locking screw C

2.Adjustment of pressing distance

A in the above picture is the pressing distance,the choice of A is 0.1-0.2mm smaller than the plate. When A is greater than the thickness of plate, the plate can’t be pressed. When A is much smaller than the thickness of the plate, the plate will be compressed due to the stress on both ends. The force causes the workbench and the compression plate to deflect, causing the two ends of the plate to be compressed and the middle to be unable to be compressed. Adjust the size of A by adjusting the piston rod of the oil cylinder, and both ends must be adjusted.

Don't put anything on the workbench to press beam.

a)Loosen the nut holding down the oil cylinder e

b)Select piston rod f

c)Measure the size of A

d)Locking nut e

3.Adjustment of middle pressure is not tight enough

If the pressing beam is compressed without placing the plate, the distance between the upper mold and the workbench will be significantly different between the middle and both ends.

It’s necessary to adjust the screw on the compression beam as shown below

Recent Posts

October 26, 2016

The Most Successful Engineering Contractor

Nov 05, 2025

How to choose the best plate rolling machine?

Oct 29, 2025

Key Configuration Steps for the DELEM DA-66T Tool