-

tel:

+86-13222111178 -

email:

info@ntjugao.com

Steps to Set Up DELEM DA-53T Manual Mode

Steps to Set Up DELEM DA-53T Manual Mode

Oct 15, 2025

Table of Contents

• Step 1: Accessing Manual Mode

• Step 2: Understanding Parameters

◦ Bend Parameters

◦ Force Parameters

◦ Speed Parameters

◦ Function Settings

◦ Product Properties

◦ Tool Information

◦ Auxiliary Axes

◦ Tool Setup

• Step 3: Configuring Parameters

◦ Macro Function

• Step 4: Manually Moving Axes

• Correction Function

• Diagnostic Function

• IO Status

• Frequently Asked Questions (FAQ)

• Conclusion

When configuring the manual mode of the DELEM DA-53T controller, it is crucial to clarify each operational step to achieve the optimal performance of the press brake. This article will guide you through the setup process of DELEM DA-53T Manual Mode step by step, helping you fine-tune equipment parameters efficiently and fully unlock the performance potential of the press brake.

Through Manual Mode, you can gain full control over the entire bending process, enabling precise adjustments and maximizing the quality of processed output. Whether you are using a DELEM controller for the first time or looking to optimize your existing operational settings, this article provides detailed steps to help you get started quickly and fully leverage the functional value of the press brake.

Step 1: Accessing Manual Mode

First, start the DELEM DA-53T controller. Once the device has started up completely, navigate to the main menu using the interface buttons.

Locate and select the "Manual Mode" option from the menu list; the controller interface will then switch from Automatic Mode to the Manual Mode setup interface.

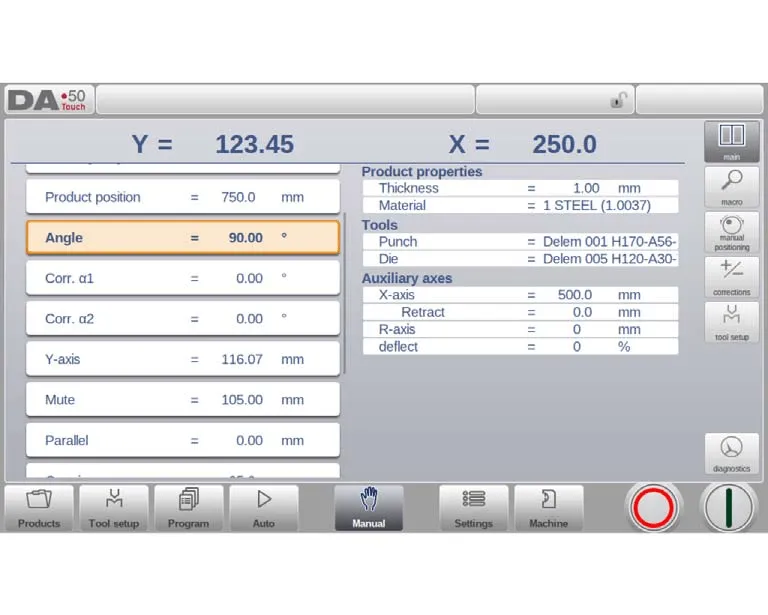

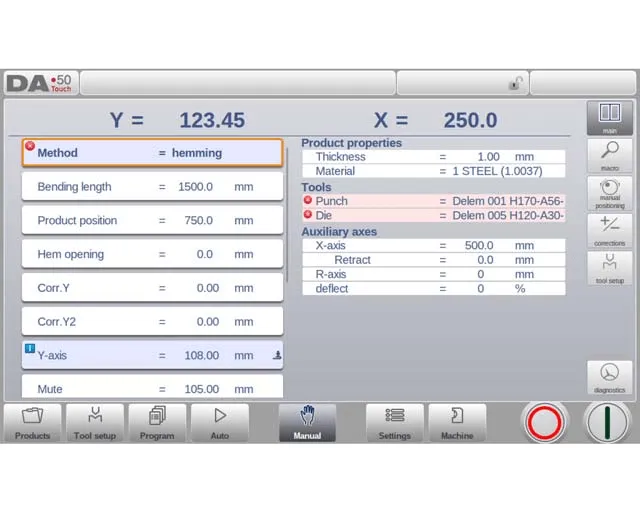

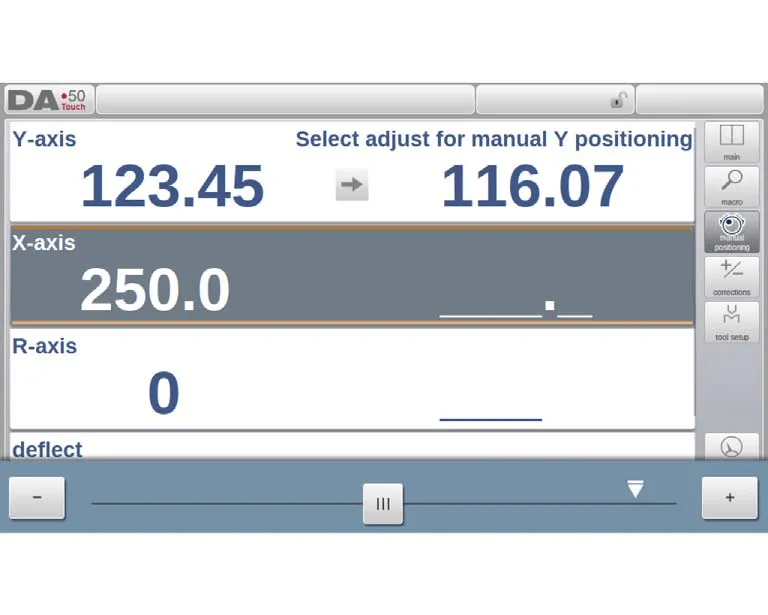

In the top area of the Manual Mode screen, you can directly view the current positions of the Y-axis and main X-axis; all other axes and functions will be listed one by one in the two columns at the bottom of the screen. If the values of the Y-axis and X-axis are highlighted, it indicates that these two axes have successfully recognized the reference marks and their current positions are consistent with the programmed values.

Step 2: Understanding Parameters

After entering Manual Mode, you need to input the required parameters for the current machining operation, including the stroke, speed, and positioning settings of the press brake—these parameters are critical to ensuring the accuracy of manual operations. Manual Mode is typically used for equipment testing, calibration, and single-bend operation scenarios.

You can input numerical values matching your expected settings using the data entry buttons. The details of the available parameters in Manual Mode are as follows:

Bend Parameters

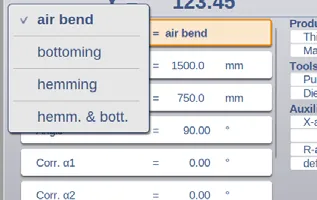

• Method: Select the required bending method. DELEM DA-53T Manual Mode supports multiple methods such as Air Bend, Bottoming, Hemming, and Hemming & Bottoming. Detailed descriptions of each method can be found in the Program Mode documentation.

• Bending Length: Input the bending length of the sheet to provide a data basis for precise machining.

• Product Position: Set and monitor the absolute position in the Z-direction using the zero point on the left side of the machine as the reference datum.

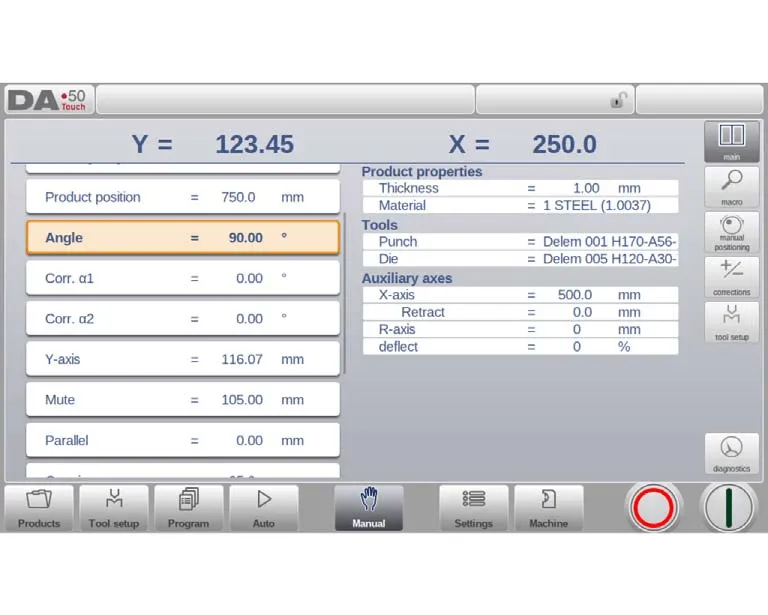

• Angle: Define the required bending angle. If there is a deviation between the actual bending angle and the expected angle, calibrate it by adjusting the correction values α1 (Corr.α1) and α2 (Corr.α2). For example, if the programmed angle is 90 degrees but the actual measured angle is 92 degrees, set Corr.α to -2.

• Hem Opening: Set the opening distance between flanges during the hemming bending process. Default parameters can be viewed in Settings Mode.

•

• Corr.Y: If the Bottoming method is selected, this parameter can be used to correct the position of the Y-axis.

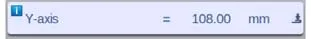

• Y-axis: The programmed or calculated Y-axis value required to achieve a specific bending angle.

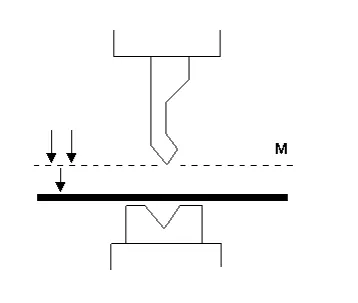

• Mute: The point at which the Y-axis switches from fast closing speed to pressing speed, programmed here as a Y-axis position value. This programmed value corresponds to the Y-axis position above the sheet.

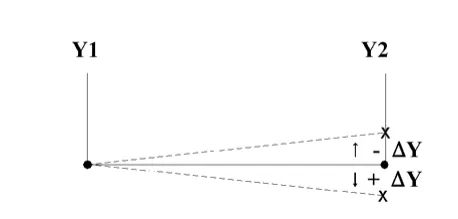

• Parallel: The position difference between the left and right cylinders (Y1 and Y2). If the value is positive, it indicates that the right cylinder is lower; if the value is negative, the right cylinder is higher. This programmed value takes effect below the clamping point.

• Opening: This parameter is used to set the gap between the punch and the die after bending is completed. A positive value means the gap is above the Mute point; a negative value means the gap is below the Mute point. If you want to shorten the product handling time, you can set this parameter to a small positive or negative value.

Force Parameters

• Force: Program the pressing force required for the bending operation to ensure the pressure application meets the machining requirements and achieves the best results.

• Dwell Time and Decompression: Set the dwell time at the bending point and the decompression distance to control the pressure release process reasonably and ensure machining stability.

Speed Parameters

• Speed: The moving speed of the Y-axis during the bending process.

• Decomp speed: The programmable moving speed of the beam within the decompression distance.

Function Settings

• Wait for Retract: Set whether the Y-axis waits for the retraction action to complete before moving, or starts moving as soon as retraction begins, to optimize workflow efficiency.

Product Properties

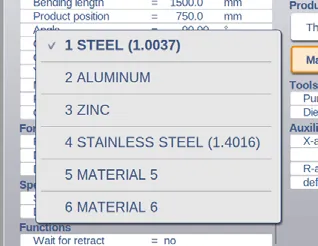

• Thickness and Material: Input the sheet thickness and select the corresponding material from 99 custom material options in the controller to provide key data support for calculating the bending depth.

Tool Information

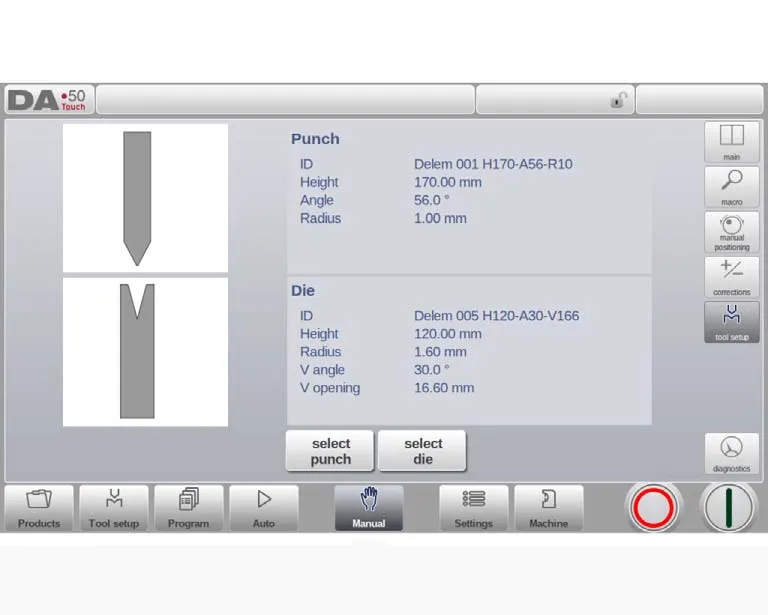

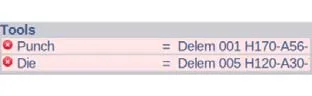

• Punch and Die: Select or modify the punch and die IDs required for the current operation from the corresponding tool libraries to ensure the tools match the machining requirements.

Auxiliary Axes

• Auxiliary Axis Parameters: If the equipment is equipped with one or more auxiliary axes (such as X-axis, R-axis, or Z-axis), their related parameters will be displayed here.

• Retract: The retraction distance of the auxiliary axis during the bending process. Among them, "Backgauge Retract" starts from the clamping point.

• Speed: The moving speed of the auxiliary axis in the current bending operation, which can be programmed as a percentage of the maximum speed.

By properly programming the above parameters in DELEM DA-53T Manual Mode, you can ensure the accuracy of the bending operation. After confirming all parameter settings are correct, press the Start button to activate these configurations.

Tool Setup

The tool setup programming in DELEM DA-53T Manual Mode is very similar to that in Automatic Mode. Both modes allow for independent tool setup, and the tool setup from Automatic Mode can be directly applied to Manual Mode. When switching to Manual Mode, the DELEM DA-53T controller will provide an option to "use the existing tool setup". However, note that if the current setup differs from the previous programming, the user must operate with caution to avoid affecting machining accuracy.

• Adding Tools (Punches/Dies): Consistent with the operation in the "Tool Setup" function, the required punches or dies can be added through the "Add" function.

Step 3: Configuring Parameters

Each parameter in DELEM DA-53T Manual Mode can be programmed independently. The system automatically calculates the impact of each parameter on others, and the relationships between parameters are intuitively displayed through symbols and background colors for easy identification by the user.

• After a parameter is modified, an information symbol will appear on the interface to indicate that the parameter has been updated.

• If a parameter value differs from the control value calculated by the system, a star symbol will be displayed—this function is particularly useful when parameters need to be intentionally set to different values or are restricted.

![]()

• If a parameter value is set incorrectly (for example, a hemming bend is programmed but no hemming tools are equipped), an error symbol will be displayed to remind the user to make corrections.

View Options

The command buttons on the right side of the screen provide access to views other than the Main view, including Macro view, Manual Positioning view, Corrections view, and Diagnostics view.

Macro Function

When the Macro function is enabled, DELEM DA-53T Manual Mode switches to a new view, and the screen displays enlarged axis values. This layout design allows operators to clearly read the axis values even when working slightly away from the controller, improving operational convenience.

Step 4: Manually Moving Axes

Movement Procedure

To manually move an axis in DELEM DA-53T Manual Mode, use the slider at the bottom of the screen. After selecting "Manual Pos" (Manual Positioning) on the main screen, a new operation interface will pop up. Adjust the slider from its middle position to the desired direction to move any axis displayed on the interface; the slider will automatically return to the middle position when released.

Moving Auxiliary Axes

Before moving an auxiliary axis, ensure the controller is in a stopped state (press the Stop button). First, select the required backgauge axis, position the cursor on that axis, and then control the movement of the axis using the slider.

Moving the Y-Axis

The operation of manually moving the press beam (Y-axis) is similar to that of auxiliary axes, but the following conditions must be met:

1. The controller must be in an activated state (press the Start button).

2. Activate the "adjust" function—if this function is not activated, a prompt message will appear in the upper right corner of the screen.

3. The Y-axis must be below the Mute point.

4. A CNC pressing command must be issued.

Position Storage (Teach)

After manually moving an axis, if you need to store the current position, click the axis name in the "Programmed" column. The system will then copy the value from the "Actual" column (left side) to the "Programmed" column (right side).

When returning to the default Manual Mode screen, the parameter of this axis will retain the most recently stored value.

Following the above steps ensures smooth and accurate axis movement operations in DELEM DA-53T Manual Mode.

Correction Function

In DELEM DA-53T Manual Mode, the correction parameters for the bending operation programmed in this mode are displayed.

Since Manual Mode typically involves a single bending operation, only one line of correction information is displayed on the interface. The programmed correction values in Manual Mode can be verified in the same way as those in Automatic Mode. Additionally, records in the correction database and initial correction values are also visible here. Accessing the correction database is crucial, as the records within it have a significant impact on the final bending results. This function is particularly useful for adjusting correction values during test bending and storing the optimal results in the database.

Diagnostic Function

In DELEM DA-53T Manual Mode, clicking "Diagnostics" allows you to view the status of each axis. This window displays the current status of all available axes and remains active even after the controller is started. Using this function enables real-time monitoring of the controller's operating status during the bending cycle, further improving operational accuracy.

IO Status

In DELEM DA-53T Manual Mode, clicking the "I/O" tab in the Diagnostics interface provides a comprehensive view of the current status of inputs (I) and outputs (O). This interface remains active after the controller is started, allowing operators to effectively monitor the system's operating status throughout the bending cycle and detect anomalies in a timely manner.

Zoomed IO View

If you click on one or more (up to 5) pins, the system will generate an additional "Zoomed IO" page, which displays the selected IO in an enlarged view. The selected pins will be shown in a larger size, facilitating monitoring by operators from a distance and improving operational flexibility.

Frequently Asked Questions (FAQ)

1. What precautions should be taken when operating the DELEM DA-53T in Manual Mode?

When operating, you must comply with all safety regulations: carefully inspect the work area to ensure there are no obstacles; wear protective equipment; and familiarize yourself with the functions of the manual control buttons to avoid accidents during operation.

2. What is the recommended maintenance frequency for the DELEM DA-53T when in Manual Mode?

Routine maintenance should be performed every 500 hours of equipment operation, including checking the integrity of key components, cleaning the equipment surface, and lubricating moving parts, to ensure smooth operation of the equipment and extend its service life.

3. Can DELEM DA-53T Manual Mode be used for all types of bending operations?

Although DELEM DA-53T Manual Mode is highly versatile, it is mainly designed for operation scenarios that require manual adjustment and real-time monitoring. For more complex or automated operations, it is recommended to use the CNC functions of the DA-53T to improve efficiency and accuracy.

Conclusion

When configuring DELEM DA-53T Manual Mode, following the steps outlined in this article is key to ensuring the normal operation of the equipment and achieving optimal performance. The entire process includes starting the controller, selecting the manual operation mode, and configuring the necessary parameters to meet the specific requirements of the press brake. This concise and systematic operation method helps improve work efficiency and reduce operational errors.

Proper equipment setup and regular maintenance are crucial to extending the service life of the press brake and ensuring its performance. By following the guidelines in this article and conducting regular maintenance, you can minimize equipment downtime and improve production efficiency. If you encounter further detailed issues or require technical support, please feel free to contact our team. Additionally, we recommend that you browse other documents available on our official website to obtain more professional insights and technical assistance.

Recent Posts

October 26, 2016

The Most Successful Engineering Contractor

Nov 05, 2025

How to choose the best plate rolling machine?

Oct 29, 2025

Key Configuration Steps for the DELEM DA-66T Tool

![Smart equipment attracts global attention, and [Jugao Exhibition Hall] welcomes a wave of negotiations at the Canton Fair](https://shopsource.singoo.cc/1187/general/XTBdt5QeSjHYM3Rs/图片222.webp?x-oss-process=image/resize,w_100/quality,q_100)