-

tel:

+86-13222111178 -

email:

info@ntjugao.com

Optimizing Bending Processes for Superior Quality in Metal

Optimizing Bending Processes for Superior Quality in Metal

Apr 17, 2025

Fabrication

Table of Contents

1.The Critical Role of Bending Process Optimization

-Why Bending Optimization Matters

-Key Factors Influencing Bending Quality

2.A Step-by-Step Guide to Optimizing Bending Operations

-Selecting the Right Equipment

-Precision Tooling Configuration

-Material Readiness and Handling

-Calibration and Quality Assurance

3.Troubleshooting Common Bending Challenges

-Recognizing Frequent Bending Defects

-Proactive Solutions for Consistent Results

4.Expert Answers to Press Brake FAQs

-Best Practices for Press Brake Calibration

-Maintenance Frequency for Peak Performance

5.Final Thoughts on Achieving Flawless Bends

In the competitive field of metal fabrication, optimizing bending processes is the cornerstone of delivering high-precision, defect-free products. Whether you operate a small workshop or a large-scale production facility, refining your bending techniques can dramatically improve efficiency, reduce waste, and elevate product quality. This guide delves into actionable strategies to perfect your bending operations, ensuring every bend meets exacting standards.

1.The Critical Role of Bending Process Optimization

Why Bending Optimization Matters

Precision in bending directly impacts product integrity, aesthetics, and functionality. Optimized processes minimize rework, lower material waste, and shorten production cycles—key drivers for cost efficiency and customer satisfaction.

Key Factors Influencing Bending Quality

Success hinges on three pillars:

-Equipment Capability – Matching machine specifications to material demands.

-Tooling Precision – Using dies and punches suited to the bend geometry.

-Material Consistency – Ensuring uniformity in metal properties and surface condition.

2.A Step-by-Step Guide to Optimizing Bending Operations

Step 1: Selecting the Right Equipment

Choose a press brake based on:

- Tonnage and Bed Length – Align with material thickness and bend complexity.

- Control Systems– CNC-enabled machines offer superior repeatability for intricate designs.

Pro Tip: Hydraulic brakes excel in heavy-gauge bending, while electric models provide energy savings for thin materials.

Step 2: Precision Tooling Configuration

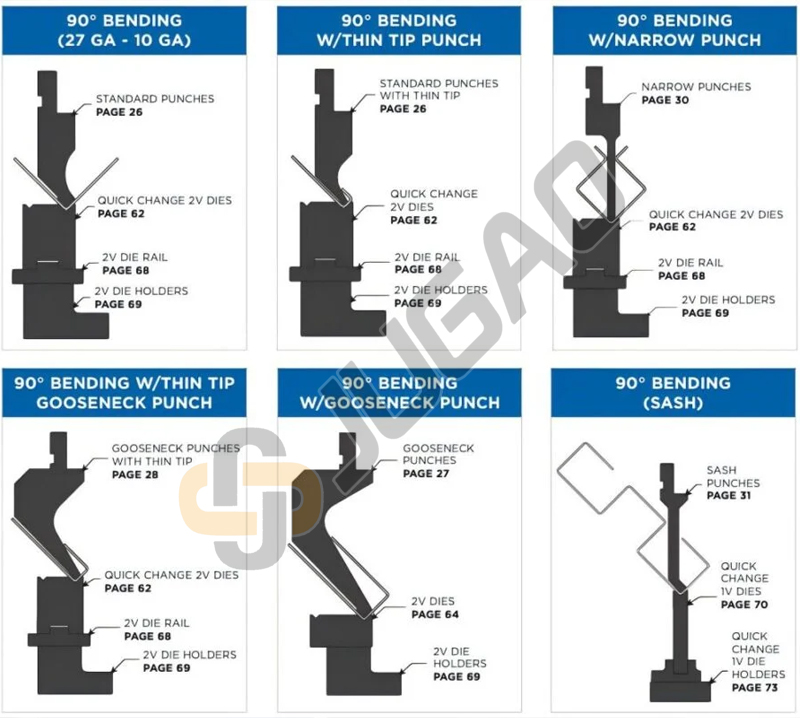

- Die and Punch Selection– Refer to manufacturer charts for optimal tool pairing.

- Avoiding Springback– Use compensating techniques or air bending for resilient metals.

Step 3: Material Readiness and Handling

- Surface Preparation– Remove contaminants like oil or scale to prevent imperfections.

- Pre-Bend Marking– Laser or scribe lines ensure bend accuracy.

Step 4: Calibration and Quality Assurance

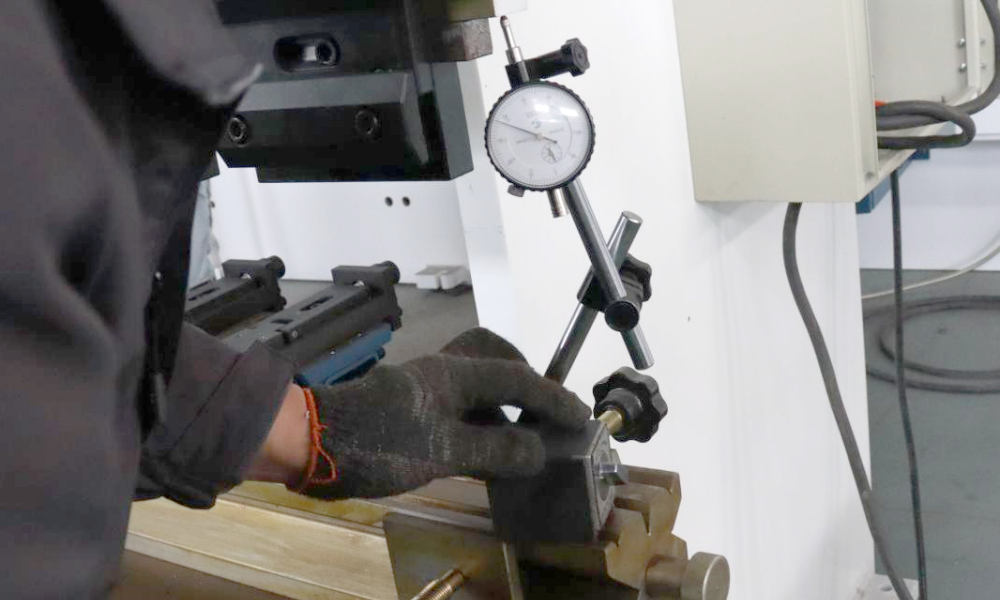

- Backgauge Alignment – Verify positioning with digital measurement tools.

- Test Bends– Conduct sample runs to validate settings before full production.

3.Troubleshooting Common Bending Challenges

Recognizing Frequent Bending Defects

- Inconsistent Angles – Often caused by tool wear or misalignment.

- Surface Scratches – Result from dirty tooling or improper material handling.

Proactive Solutions for Consistent Results

- Routine Tool Inspections – Replace worn dies promptly.

- Lubrication Protocols – Reduce friction to extend tool life and improve finish.

4.Expert Answers to Press Brake FAQs

Q: What’s the most reliable method for press brake calibration?

A: Begin with machine leveling, then use a digital angle finder to fine-tune the ram and dies. Regular laser calibration is recommended for high-volume operations.

Q: How frequently should maintenance be performed?

A: Schedule inspections every 500 operational hours, focusing on hydraulic systems, guides, and electrical components.

5.Final Thoughts on Achieving Flawless Bends

Mastering bending optimization requires a blend of technical knowledge and meticulous execution. By investing in the right equipment, maintaining rigorous standards, and addressing issues proactively, fabricators can achieve unparalleled precision and efficiency. For tailored advice or advanced troubleshooting, consult with JUGAO CNC MACHINE to keep your operations at the cutting edge.

Optimize today—excel tomorrow.

Key Takeaways:

✔ Prioritize equipment and tooling compatibility.

✔ Implement strict material prep and calibration routines.

✔ Adopt preventive maintenance to sustain performance.

This revised version enhances clarity, flow, and practicality while preserving the original’s technical foundation. If you'd like further refinements, Contact JUGAO CNC MACHINE!

Recent Posts

October 26, 2016

The Most Successful Engineering Contractor

Nov 05, 2025

How to choose the best plate rolling machine?

Oct 29, 2025

Key Configuration Steps for the DELEM DA-66T Tool