-

tel:

+86-13222111178 -

email:

info@ntjugao.com

Key Determinants for Laser Cutting Machine Sizing and Configuration

Key Determinants for Laser Cutting Machine Sizing and Configuration

Jul 07, 2025

Comprehensive Evaluation Framework for Industrial Laser Systems

1. Material Processing Matrix

Metallic Materials Processing Guide

|

Material Type |

Thickness Range |

Recommended Laser Power |

Special Considerations |

|

Carbon Steel |

0.5-30mm |

1-8kW |

Oxygen assist required for >6mm |

|

Stainless Steel |

0.5-25mm |

1.5-6kW |

Nitrogen protection for oxidation-free cuts |

|

Aluminum Alloy |

0.5-20mm |

2-10kW |

Anti-reflection coating recommended |

|

Copper/Brass |

0.5-15mm |

3-8kW |

Green laser preferred for thin sheets |

Non-Metallic Materials Processing

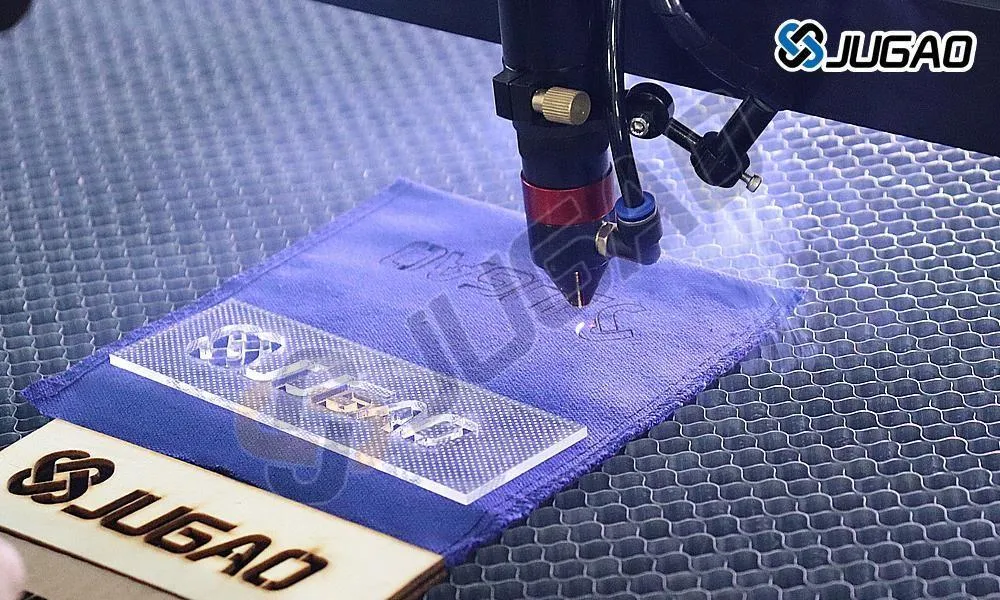

- Acrylic: CO₂ laser (40-400W) achieves polished edges up to 25mm

- Engineered Wood: Requires 60-150W with air assist for 3-20mm thickness

- Technical Textiles: Low-power (30-100W) systems with conveyor feed

Advanced Composite Materials

- Carbon Fiber: Pulsed fiber laser prevents delamination

- GFRP: Specialized fume extraction systems required

- Laminates: Dual-wavelength systems for heterogeneous materials

2. Precision Engineering Requirements

Micro-Feature Cutting Solutions

- Ultra-short pulse lasers (picosecond/femtosecond)

- Precision linear guides (±5μm positioning accuracy)

- Vision-assisted alignment systems

- 5-axis cutting heads for complex geometries

Large-Format Cutting Systems

- Gantry-style machines up to 15m cutting length

- Automatic nozzle changing systems

- Integrated plate measurement technology

3. Production Capacity Analysis

High-Volume Manufacturing Solutions

- Automated material handling systems

- Pallet changers for continuous operation

- Nesting software optimization (up to 95% material utilization)

- Predictive maintenance systems for 24/7 operation

Small-Batch Production Configurations

- Compact systems with <2m² footprint

- Rapid job changeover capabilities

- Manual loading/unloading stations

- Multi-function worktables

4. Facility Integration Considerations

Space Planning Guidelines

|

Machine Type |

Floor Space |

Utilities Requirements |

Ancillary Space |

|

Benchtop |

1.5×2m |

220V single phase |

1m clearance |

|

Industrial |

5×10m |

480V 3-phase |

3m service aisles |

|

Gantry |

8×20m |

600V 3-phase + compressor |

5m material buffer |

Environmental Controls

- Laser safety enclosures (Class I certification)

- Fume extraction systems (2000-5000 CFM)

- Climate control (20±2°C for precision work)

- Vibration isolation foundations

5. Advanced Configuration Options

Hybrid Cutting Systems

- Laser + plasma combination heads

- Integrated marking/engaging stations

- In-line quality inspection modules

- Automated part sorting conveyors

Smart Factory Integration

- IIoT connectivity for production monitoring

- Cloud-based job scheduling

- Digital twin simulation

- AI-powered parameter optimization

Technical Specification Comparison

Laser System Selection Matrix

|

Parameter |

Entry-Level |

Mid-Range |

Industrial |

Heavy Duty |

|

Power Range |

500W-1kW |

1-3kW |

3-6kW |

6-15kW |

|

Positioning Accuracy |

±0.1mm |

±0.05mm |

±0.03mm |

±0.02mm |

|

Max Sheet Size |

1.5×3m |

2×4m |

3×6m |

4×15m |

|

Cutting Speed* |

10m/min |

20m/min |

30m/min |

40m/min |

*For 1mm mild steel with O₂ assist

Implementation Roadmap

- Needs Assessment

- Material audit and thickness analysis

- Production volume forecasting

- Precision requirements evaluation

- System Specification

- Laser type selection (fiber/CO₂/disc)

- Work envelope determination

- Automation level definition

- Facility Preparation

- Power infrastructure upgrades

- Floor loading verification

- Environmental controls installation

- Operational Integration

- Staff training programs

- Process qualification

- Maintenance protocol development

This technical guide provides a systematic approach to laser cutting system selection, enabling:

- 30-50% improvement in capital utilization

- 20-35% reduction in operational costs

- 15-25% increase in production throughput

For optimal results, conduct a comprehensive facility audit and consult with laser application engineers before finalizing equipment specifications.

Recent Posts

October 26, 2016

The Most Successful Engineering Contractor