-

tel:

+86-13222111178 -

email:

info@ntjugao.com

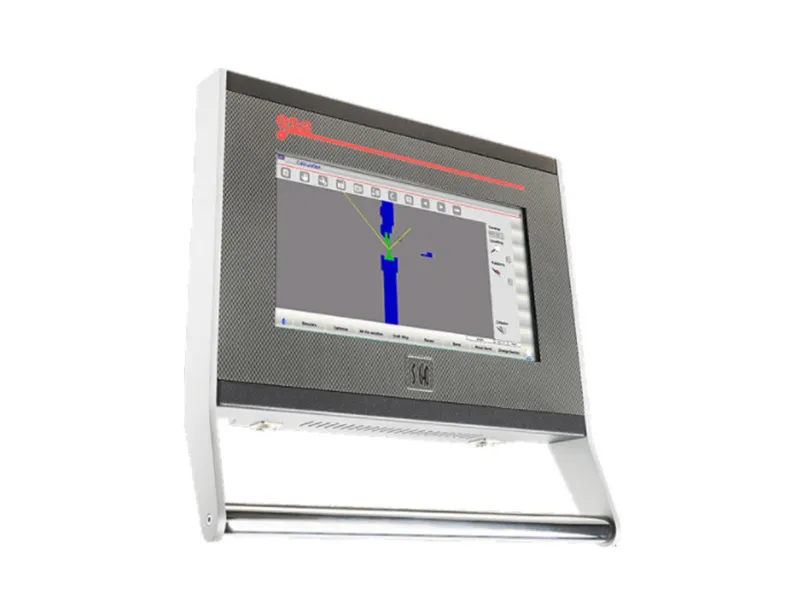

ESA S640 2D Graphical CNC System

ESA S640 2D Graphical CNC System

Aug 31, 2025

CNC bending machine system

Successfully controlling precision & productivity, modern sheet metal production is inconceivable without high performance software. Highly effective control algorithms optimize the machine cycle, reduce the time required for set-up and ensures consistently high quality.

ESA CNC Control System

ESA S640 2D Graphical CNC System

Top-level performances for machines up to six axes with automatic bending sequence calculations and Material Data Base for predictive compensation are available (as options) to reduce the wastage of material.

1. 15 inch LCD touch screen (Resistive)

2. Touch 2D graphic part creation with automatic sequence

3. Stander to 4 axis, can up to 6 axis max.

4. Automatic bending force, crowning calculation.

5. Modulable tools for each part or bend.

6. Direct angle correction, also for the crowning.

7. Proprotional and pressure valve Amplify intergrated.

8. Free off-line PC simulation software.

9. Tandem machine management(option, can up to 4 machines)

10. Modbus TCP interface for SCADA or MES(option)

TYPICAL APPLICATIONS

● Conventional press-brakes (Mechanical and Hydraulic), synchro Hydraulic press-brakes, servo controlled hydraulic single cylinder press-brakes, electrically driven press-brakes

● Hydro-mechanical press-brakes American style software specifications

● Interactive 2d graphic editor for work-pieces and tools data entry

● 2D graphic display of machine frame, work-piece and tools

● Manual 2D graphic identification of the best bending sequence

● Programming of the axes positions in tabular mode with automatic syntax checks, automatic calculation of the r, z and A positions and of the bending and crowning tonnage

● Windows® like user interface

● Complete off-line programming on a standard pc

● IEC 61131-3 plc programming language with function utilities either written in il or “c” language, are available for manufacturers

● Customizable alarm messages

GENERAL SPECIFICATIONS

● 15” touch screen panel (resolution WSVGA 1366x768)

● FPGA integrated logics, surface mounting, fiber optic

● Cpu Via Nano X2 E 1,2 Ghz with 2Gb of RAM

● Silicon hard disk (flash disk) for more than 30.000 part programs

● 2 serial ports rs-232

● 2 USB port for memory stick

● 1 ethernet port

● 2 can open port

● Fiber optic interface

● Local area network

Compact with high performances. 15” touch screen

Top-level performances for machines up to six axes. The wide screen allows excellent comfort for the operator enhancing the advantages of a full graphic interface.

Automatic bending sequence calculations and Material Data Base for predictive compensation are available (as options) to reduce the wastage of material.

Crowning correction in degrees.

Dynamic crowning is available to grant the perfect bend linearity.

Direct connection of Mitutoyo protractor e Anglecheck device to allow in process angle measurement.

Recent Posts

October 26, 2016

The Most Successful Engineering Contractor

Nov 05, 2025

How to choose the best plate rolling machine?

Oct 29, 2025

Key Configuration Steps for the DELEM DA-66T Tool