-

tel:

+86-13222111178 -

email:

info@ntjugao.com

Common Mistakes in Press Brake Operation

Common Mistakes in Press Brake Operation

Sep 23, 2025

Bending machines (press brakes) are critical in metal fabrication for creating precise bends in sheet metal. However, improper operation can lead to defects, machine damage, and safety hazards. This document examines the most frequent mistakes in bending machine operation, their causes, and best practices to avoid them.

1. Common Operational Mistakes & Solutions

1.1. Incorrect Tool Selection

Mistake:

l Using mismatched punch/die combinations (wrong V-opening, radius, or tonnage).

l Applying soft tooling for hard materials (e.g., aluminum dies for stainless steel).

Consequences:

l Poor bend accuracy, excessive tool wear, or machine overload.

Solution:

l Follow manufacturer tooling guidelines.

l Use proper die width: V-die opening = 6–12× material thickness (T).

1.2. Improper Material Positioning

Mistake:

l Misaligned back gauge setting.

l Uneven clamping pressure.

Consequences:

l Inconsistent bend angles, part asymmetry.

Solution:

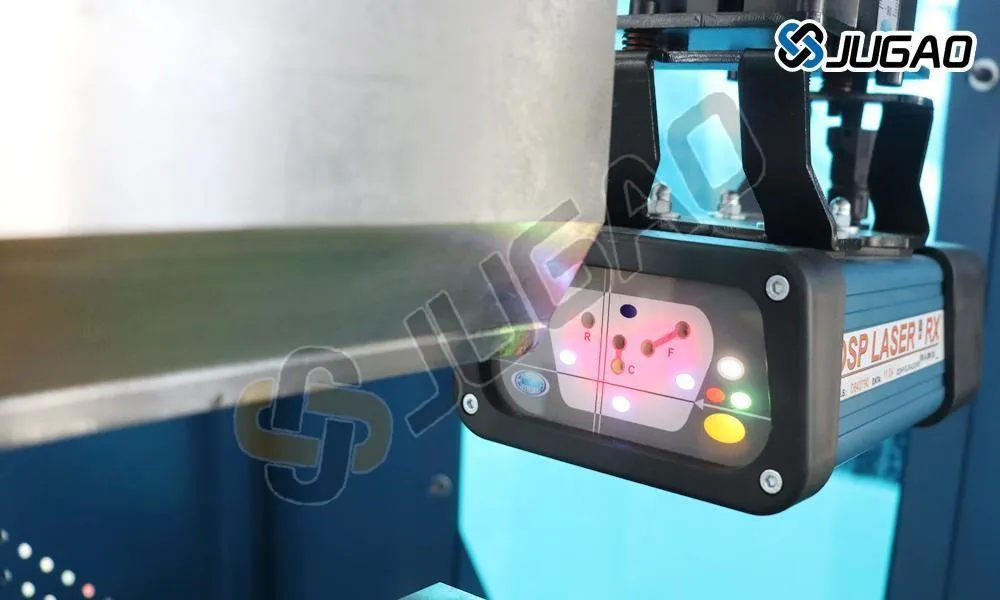

l Calibrate back gauges regularly.

l Use laser guides or CNC positioning systems.

1.3. Ignoring Material Grain Direction

Mistake:

l Bending parallel to the grain in anisotropic materials (e.g., rolled steel).

Consequences:

l Cracking, reduced bend strength.

Solution:

l Always bend perpendicular to the grain when possible.

1.4. Overloading the Machine

Mistake:

l Exceeding press brake tonnage capacity for thick materials.

Consequences:

l Ram deflection, hydraulic system damage.

Solution:

l Calculate required tonnage:

Where:

TS = Tensile strength (MPa)

L = Bend length (mm)

T = Material thickness (mm)

V = Die opening (mm)

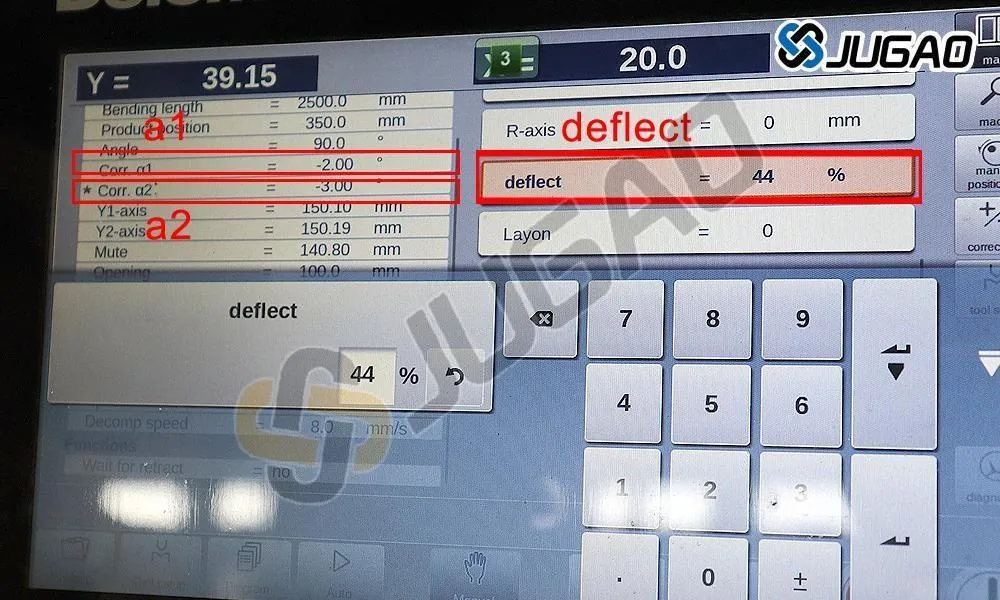

1.5. Neglecting Springback Compensation

Mistake:

l Not accounting for material rebound after bending.

Consequences:

l Under-bent parts, rework needed.

Solution:

l Overbend by 1°–5° (varies by material).

l Use CNC-controlled angle correction.

1.6. Poor Lubrication Practices

Mistake:

l Running dry bends or using incorrect lubricants.

Consequences:

l Scratched surfaces, accelerated tool wear.

Solution:

l Apply anti-friction pastes (e.g., molybdenum disulfide).

1.7. Incorrect Bend Sequencing

Mistake:

l Performing complex bends in illogical order.

Consequences:

l Tool interference, deformed flanges.

Solution:

l Follow the "inside-out" rule:

1. Bend innermost features first.

2. Progress toward outer edges.

2. Safety-Related Errors

2.1. Bypassing Safety Guards

Risk:

l Hand injuries from pinch points.

Prevention:

l Never disable light curtains/finger guards.

2.2. Improper Handling of Large Sheets

Risk:

l Dropped materials, muscle strains.

Prevention:

l Use vacuum lifters or crane assists.

3. Troubleshooting Defects

|

Defect |

Likely Cause |

Correction |

|

Cracking |

Radius too tight |

Increase bend radius |

|

Wrinkling |

Insufficient pressure |

Adjust tonnage |

|

Angle inconsistency |

Worn tools |

Replace punch/die |

|

Surface marks |

Dirty/damaged dies |

Clean/polish tools |

4. Best Practices for Error Prevention

l Operator Training – Regular CNC/programming refreshers.

l Preventive Maintenance – Check hydraulic systems, guides.

l Job Planning – Verify CAD/CAM simulations before production.

l Quality Checks – First-article inspection with protractors.

5. Conclusion

Avoiding common bending mistakes requires understanding material behavior, tooling physics, and machine limits. Implementing structured workflows and safety protocols minimizes scrap while maximizing productivity.

Recent Posts

October 26, 2016

The Most Successful Engineering Contractor

Nov 05, 2025

How to choose the best plate rolling machine?

Oct 29, 2025

Key Configuration Steps for the DELEM DA-66T Tool