-

tel:

+86-13222111178 -

email:

info@ntjugao.com

A complete analysis of the necessary equipment for sheet metal processing projects

A complete analysis of the necessary equipment for sheet metal processing projects

Aug 06, 2025

Overview of sheet metal processing equipment

As a basic process in modern manufacturing, sheet metal processing requires a series of professional equipment to complete key processes such as cutting, bending, forming and shearing. These equipment, from traditional hand tools to advanced CNC machine tools, constitute a complete sheet metal processing system.

Classification of core processing equipment

1. Bending and forming equipment

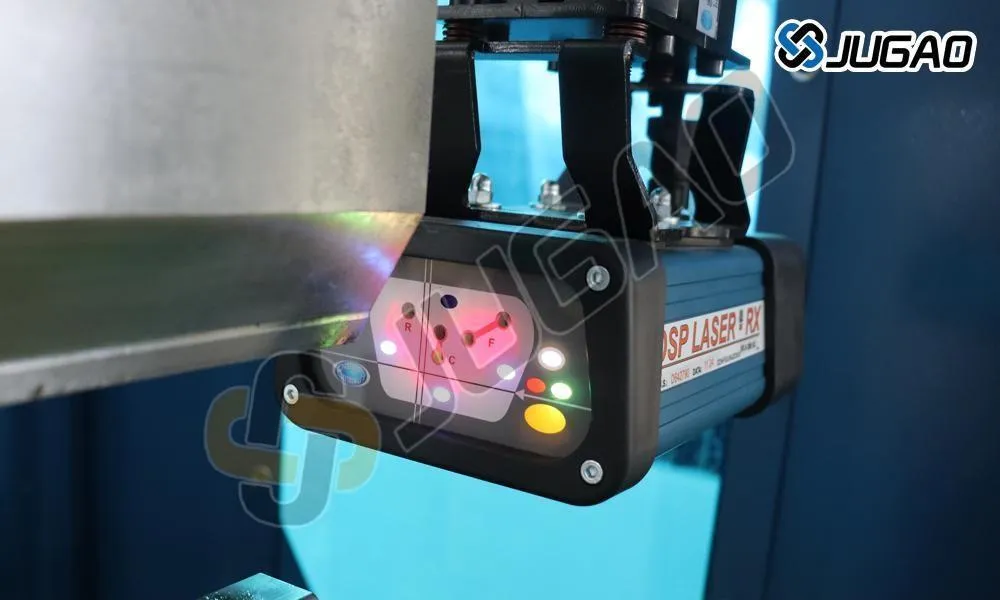

CNC Press brake is the core equipment of modern sheet metal bending, with the following characteristics:

l Adopt hydraulic or servo motor drive system

l Equipped with high-precision back gauge (accuracy can reach ±0.01mm)

l Programmable control of multi-axis linkage

l Typical processing thickness range: 0.5-25mm

Auxiliary bending equipment includes:

l Bench Press brake: suitable for small workpiece processing, the maximum processing length is usually 1-2 meters

l Pipe bending machine: specially used for bending of pipes and special-shaped materials

l Manual folding machine: suitable for simple bending operations with small batches and low precision requirements

2. Cutting equipment series

Mainstream CNC cutting equipment:

l Laser cutting machine: processing accuracy can reach ±0.05mm, suitable for complex contour cutting

l Plasma cutting machine: suitable for thick plate cutting (up to 50mm)

l Water jet cutting machine: no heat affected zone, suitable for special material processing

Traditional cutting tools:

l Electric shearing machine: maximum shearing thickness can reach 6mm

l Manual shearing tools: including straight shear, circular shear and combination shear

l Metal punching and shearing machine: suitable for large-scale standard shape cutting

3. Forming and processing equipment

Advanced forming equipment:

l Hydraulic pressing machine: working pressure can reach more than 2,000 tons

l Roll forming production line: continuous processing length can reach tens of meters

l Spinning machine: suitable for precision forming of axisymmetric parts

Special forming tools:

l Rolling machine: three-roll or four-roll structure, can process 3-50mm plates

l Flanging machine: used to make various flange edges

l Bulging machine: realize local expansion forming of pipes

4. Shearing and finishing equipment

Professional shearing equipment:

l CNC shearing machine: Maximum shearing length can reach 6 meters

l Swing shearing machine: Adjustable shearing angle to reduce deformation

l Vibration shearing machine: Suitable for shearing of complex curves

Surface treatment equipment:

l Deburring machine: Automatically removes burrs on cutting edges

l Polishing machine: Achieve mirror effect on the surface

l Sandblasting machine: Improve surface adhesion and appearance

Equipment Selection Guide

Considerations:

1. Material properties

l Stainless steel: It is recommended to use a high-power laser cutting machine

l Aluminum alloy: Suitable for water jet or mechanical cutting

l Carbon steel: The most versatile, suitable for most equipment

2. Production scale

l Small batch: manual + semi-automatic equipment combination

l Medium batch: CNC single machine configuration

l Large batch: automated production line

3. Precision requirements

l Ordinary level: ±0.5mm

l Precision level: ±0.1mm

l High precision level: ±0.02mm

Modern sheet metal processing trends

1. Intelligent development

l Equipment networking and remote monitoring

l Automatic programming and process optimization

l Intelligent detection and compensation system

2. Compound processing technology

l Cutting-bending integrated equipment

l 3D printing and sheet metal composite process

l Laser cutting and welding composite machine

3. Green manufacturing

l Energy-saving servo drive system

l Automatic waste recycling device

l Environmentally friendly cooling technology

Equipment maintenance and management suggestions

1. Daily maintenance

l Regular lubrication of moving parts

l Check hydraulic system pressure

l Clean foreign objects on the work surface

2. Precision maintenance

l Monthly equipment accuracy inspection

l Replace worn tools in time

l Calibrate measurement system

3. Safe operation

l Equipped with safety protection devices

l Professional training for operators

l Establish equipment operation specifications

By rationally configuring the above equipment and adopting scientific processing technology, enterprises can establish an efficient and accurate sheet metal processing system to meet various processing needs from simple parts to complex components.

Recent Posts

October 26, 2016

The Most Successful Engineering Contractor

Nov 05, 2025

How to choose the best plate rolling machine?

Oct 29, 2025

Key Configuration Steps for the DELEM DA-66T Tool