-

tel:

+86-13222111178 -

email:

info@ntjugao.com

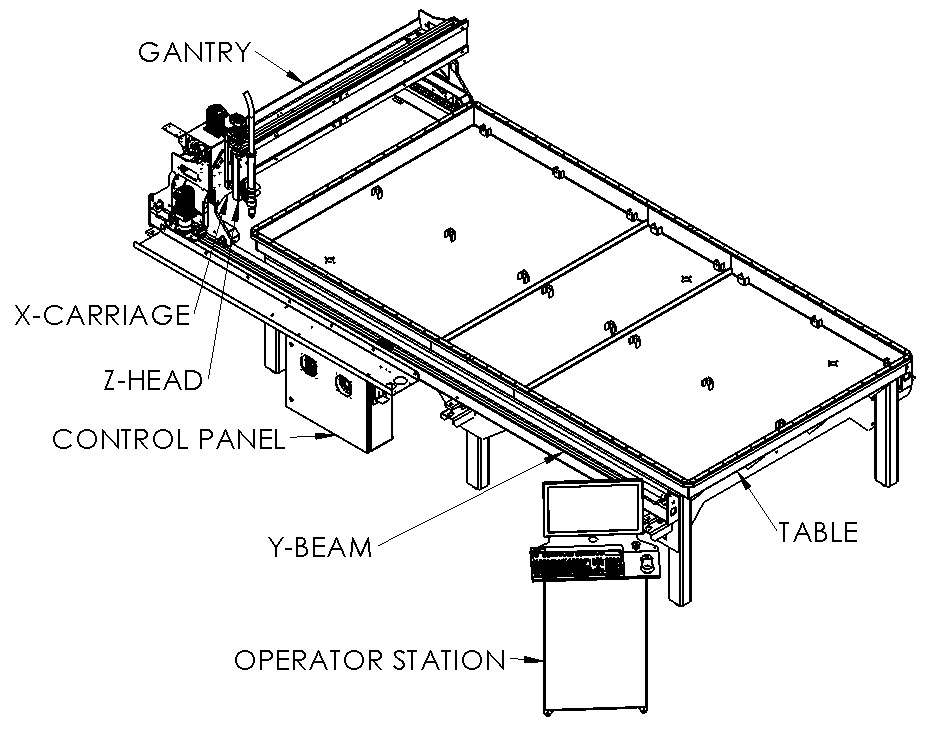

65A-3015 Working table type CNC plasma cutting machine

65A-3015 Working table type CNC plasma cutting machine

Product Features

1. Using highly-precise linear guides, double-sided synchronized drive, The machine works noiselessly with high speed and high precision.

2. Human-computer interface design makes the machine easy to learn and operate, and have complete functions.

3. Have 7 inch color LCD display and operate panel, and read program and software upgrade by USB flash disk.

4. Have the function of wireless of automatically memorizing and restoring when power is off.

5. According to the structure of the machine, we can supply work piece collect drawer cutting table, or smoke and dust collector with work piece collect drawer cutting table.

6. System can detect location and enjoys high precision, wide speed range and short acceleration time.

7. Can effectively avoid high frequency interference, and make cutting stable and safe.

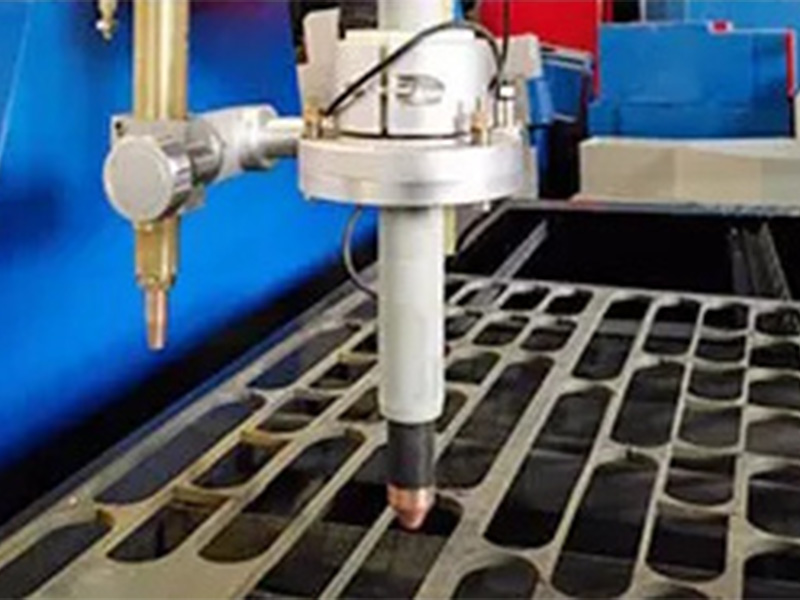

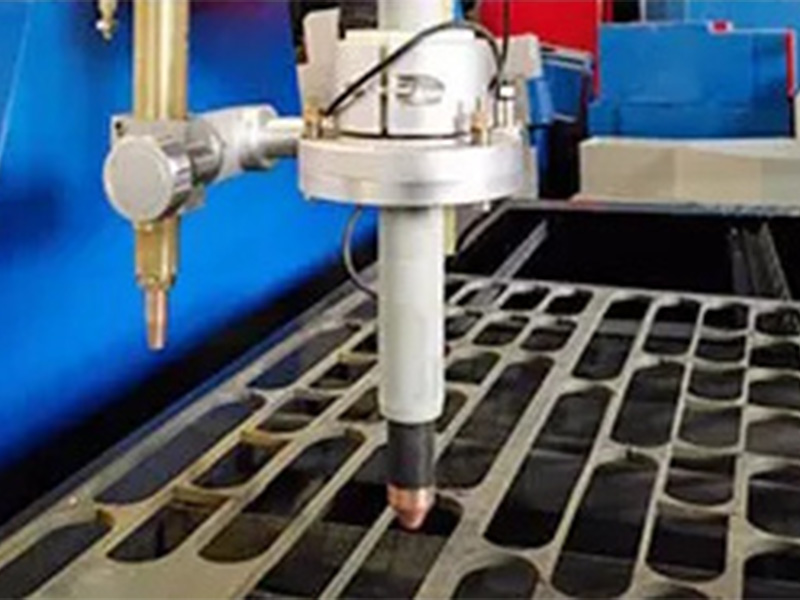

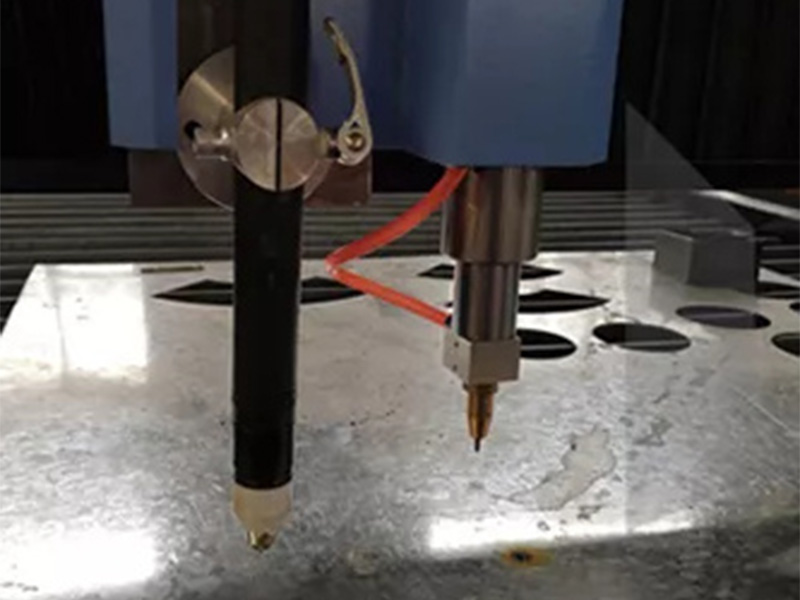

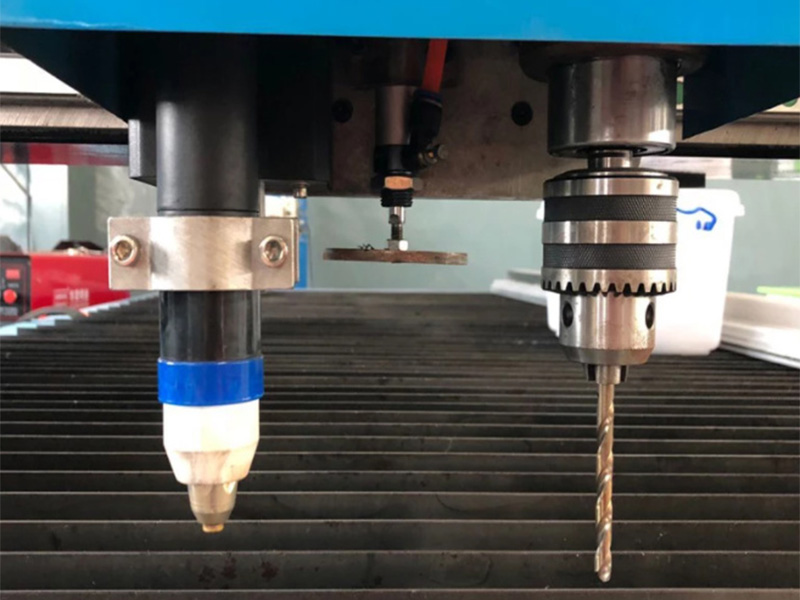

Sample show

Technical parameter

|

NO. |

NAME |

DATA |

UNIT |

REMARKS |

|

|

1 |

Working Size |

1500X3000 |

mm |

|

|

|

2 |

Output Current |

65 |

A |

|

|

|

3 |

Max cutting thick in steel |

8 |

mm |

|

|

|

Max cutting thick in stainless |

4 |

||||

|

4 |

Z Axis Clearance |

200 |

mm |

|

|

|

5 |

Move precision |

±0.1 |

mm |

|

|

|

6 |

Positioning precision |

±0.15 |

mm |

|

|

|

7 |

Max. Cutting Speed |

12000 |

mm/Min |

|

|

|

8 |

Max. Travelling Speed |

20000 |

mm/Min |

|

|

|

9 |

Gas pressure |

0.4 |

MPa |

|

|

|

10 |

Working temperature |

-10-60 |

°C |

|

|

|

11 |

Table height |

850 |

mm |

|

|

|

12 |

Total Power consumption(without Plasma system ) |

4 |

Kw |

|

|

|

13 |

Machine Dimension |

Length |

3400 |

Mm |

|

|

Width |

2300 |

Mm |

|

||

|

Height |

1800 |

Mm |

|

||

|

14 |

Weight |

1600 |

Kg |

||

Accessories brand list

|

No. |

Name |

Model/Manufacturer |

Other |

Configuration |

|

1 |

CNC System |

þStarfire Controller |

Standard |

|

|

2 |

Nesting Software

|

FASTCAM

|

||

|

3 |

File transfer mode |

USB interface |

||

|

4 |

Plasma Generator |

Huayuan China |

||

|

5 |

Plasma torch |

Blackwolf |

||

|

6 |

Electrics |

Germany Schneider electric |

||

|

7 |

Motor for Driving System |

Siemens stepper motor and drivers |

||

|

8 |

Table Type |

Saw tooth table |

||

|

9 |

Transmission System |

Rack Pinion And Linear Rails For X/Y/Z |

||

|

10 |

Arc Mode |

Non-Contact Arc, Arc Pressure Adjuster |

||

|

11 |

Torch Height Control(THC) mode |

Automatic High sensitive THC |

||

|

12 |

Type of gas needed |

Air |

||

|

13 |

Floating cutting gun mode of motion |

Automatic and Pneumatic test |

||

|

14 |

Plasma Generator |

Hypertherm USA |

Optional |

|

|

15 |

Servo Driving System |

Panasonic Japan |

||

|

16 |

Pipe cutting device |

Made by JUGAO |

||

|

17 |

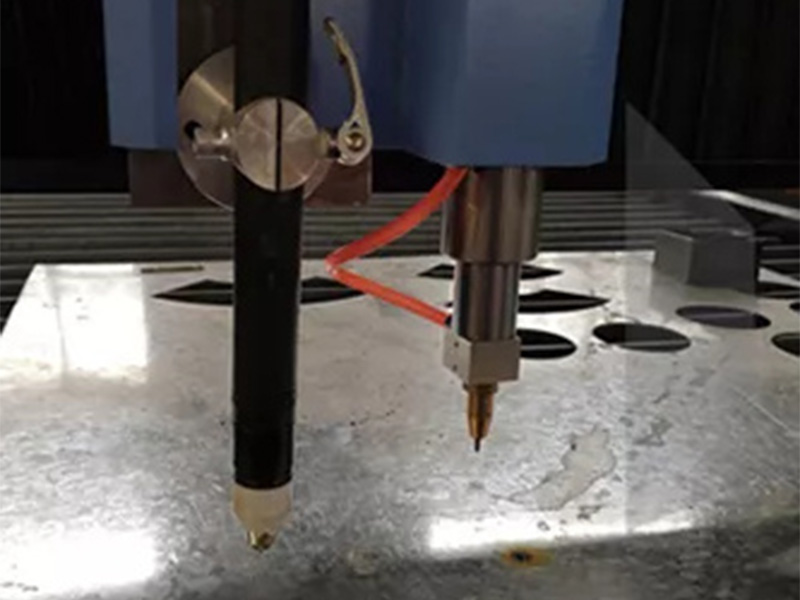

Flame cutting device |

Made by JUGAO |

||

|

18 |

Mark device |

Made by JUGAO |

||

|

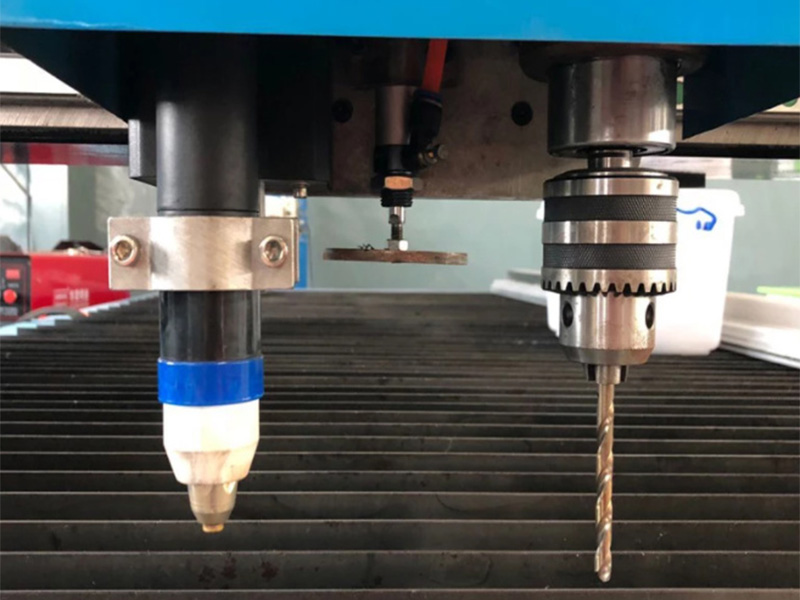

19 |

Drilling Device |

Made by JUGAO |

||

|

20 |

Water Table |

Made by JUGAO |

||

|

21 |

Safety standard |

þCE ¨CSA þNR-12 ¨OSHA |

||

SPARE PARTS AND SPECIAL TOOLS

|

Accessory |

||||

|

1 |

GB801-2011 |

Bolt M16X500 |

Piece |

4 |

|

2 |

GB7160-2016 |

Nuts M16 |

Piece |

4 |

|

3 |

GB98-2015 |

Inflatable tools |

Piece |

1 |

|

4 |

GB610-2014 |

Electrical box key |

Piece |

1 |

|

5 |

GB766-2018 |

Button box power key |

Piece |

2 |

|

Spare parts |

||||

|

6 |

GB689-2018 |

protective cap |

Piece |

5 |

|

7 |

Nesting Software |

FASTCAM |

Piece |

1 |

|

8 |

GB638-2018 |

nozzle |

Piece |

5 |

|

9 |

GB674-2022 |

electrode |

Piece |

5 |

LIST OF ACCOMPANYING DOCUMENTS:

|

Document |

|||

|

1 |

Manual Operation Book |

Copy |

1 |

|

2 |

Certification of CE |

Copy |

1 |

|

3 |

Packing list/Commercial Invoice( Certification of Origin) |

Copy |

1 |

|

4 |

Inspection Qualified |

Copy |

1 |

OPITION PART

Plasma Generator

-

Servo Driving System

-

Pipe cutting device

-

Flame cutting device

-

Mark device

-

Drilling Device

-

Water Table

PRODUCTS DISPLAY

Factory photos

Customer Feedback

Shipping: