-

tel:

+86-13222111178 -

email:

info@ntjugao.com

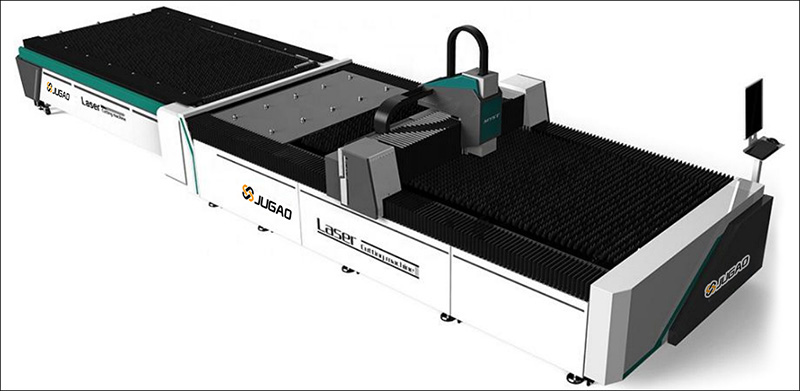

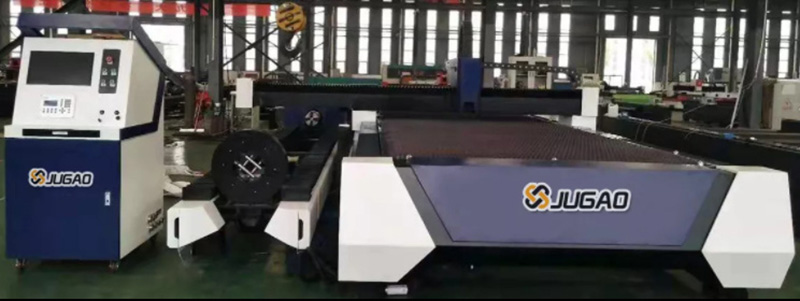

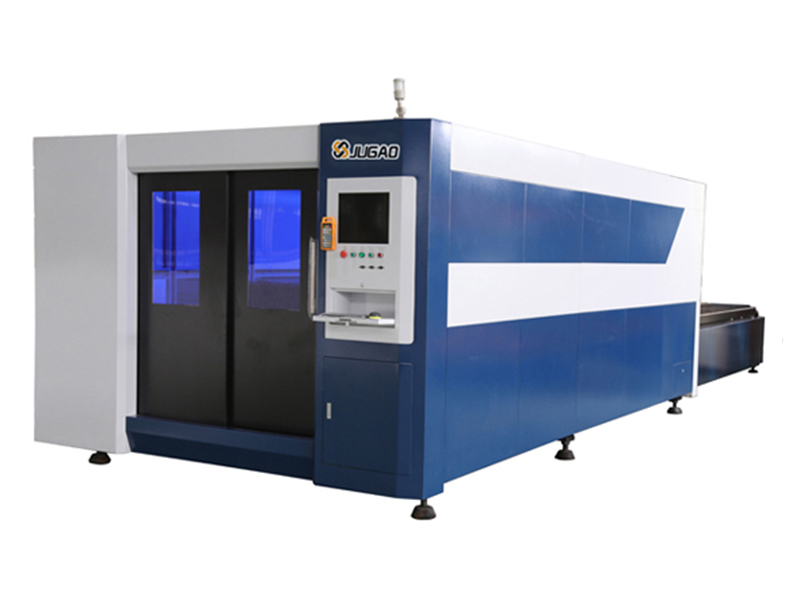

2000W CNC Fiber Laser cutting machine with 1500X3000mm working table

2000W CNC Fiber Laser cutting machine with 1500X3000mm working table

2000W Fiber Laser Cutting Machine

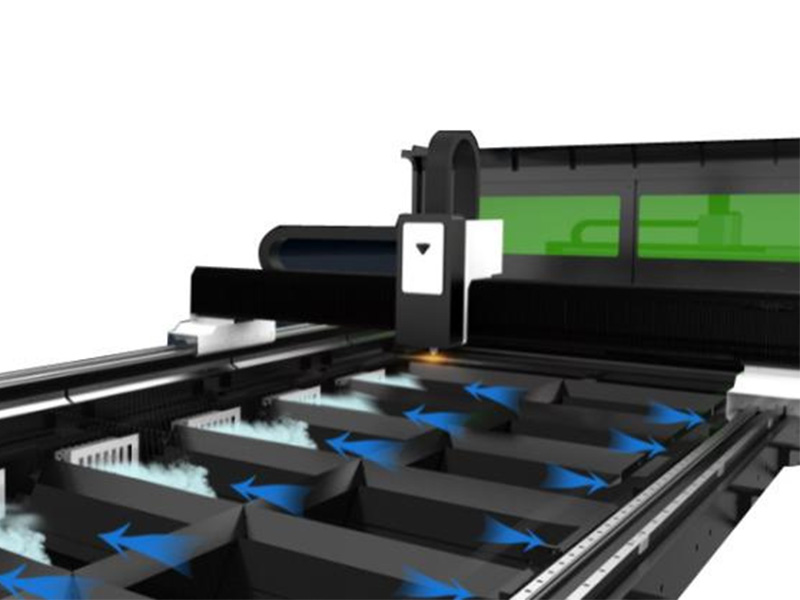

Fiber laser cutting machine adopting world famous Germany fiber laser source and Europe laser cutting head and dynamic focus system, it can cut and punch different kinds of metal material with high precision and high speed. Since laser is transmitted by fiber , it is no need to maintenance or adjusts the laser optical path , it greatly reduces the machines fault rate and prolongs the working life. Large format cutting area meets the demands of various kinds of metal processing .

Product Features

1. Excellent beam quality: Smaller focus diameter , high work efficiency, better processing quality.

2. High cutting speed: 2-3 times faster than YAG and CO2 laser .

3. High Stability: Adopt superior quality fiber laser, stable performance, key parts can reach 100,000 hours.

4. High efficiency for photoelectric conversion : Compared with CO2 laser cutting machine, Fiber laser cutting machine has 3 times photoelectric conversion and with energy saving & friendly environment .

5. Low cost: The whole power consumption is only 20-30% of traditional CO2 laser cutting machine.

6. Low maintenance cost: It is with Optical fiber line transmission, no need reflector lens, can save a lot of maintenance cost.

7. Easy Operation : Fiber Line transmission, no adjustment of optical path.

8. Super-flexible optical effect : small volume, compact structure, easy to flexible manufacturing requirements .

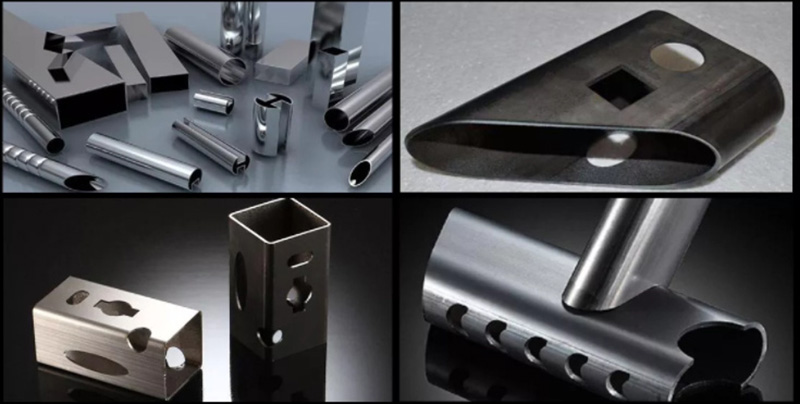

Sample show

Cutting Thickness And Speed

|

Material |

Thickness (mm) |

1000W |

1500W |

2000W |

3000W |

4000W |

|

Cutting speed m/min |

Cutting speed m/min |

Cutting speed m/min |

Cutting speed m/min |

Cutting speed m/min |

||

|

Carbon steel (O2) |

1 |

14 |

20 |

24 |

30 |

35 |

|

2 |

7 |

9 |

12 |

18 |

24 |

|

|

3 |

3.3 |

3.5 |

3.8 |

4 |

6 |

|

|

4 |

2.2 |

3 |

3.1 |

3.5 |

5 |

|

|

5 |

1.8 |

2.5 |

2.7 |

3 |

4 |

|

|

6 |

1.5 |

2 |

2.1 |

2.5 |

2.5 |

|

|

8 |

1 |

1.5 |

1.5 |

1.9 |

1.9 |

|

|

10 |

0.8 |

1.2 |

1.3 |

1.3 |

1.3 |

|

|

12 |

|

0.8 |

0.9 |

1.2 |

1.2 |

|

|

16 |

|

|

0.6 |

0.8 |

0.8 |

|

|

20 |

|

|

|

0.7 |

0.7 |

|

|

Stainless steel (Air) |

1 |

14 |

20 |

25 |

30 |

35 |

|

2 |

5 |

8 |

13 |

20 |

24 |

|

|

3 |

3 |

4 |

5.4 |

11 |

13 |

|

|

4 |

1.5 |

3 |

3.3 |

8 |

11 |

|

|

5 |

1 |

1.5 |

2.4 |

5 |

7.5 |

|

|

6 |

|

1 |

1.3 |

3 |

5 |

|

|

8 |

|

|

1 |

1.7 |

3.5 |

|

|

10 |

|

|

|

1 |

2 |

|

|

12 |

|

|

|

0.6 |

1.5 |

|

|

Aluminum plate |

1 |

9 |

18 |

21 |

24 |

27 |

|

2 |

3.6 |

7 |

9 |

14 |

17 |

|

|

3 |

1 |

2 |

6 |

8.5 |

12 |

|

|

4 |

|

1 |

3.2 |

5 |

8 |

|

|

5 |

|

|

1.5 |

3.5 |

5.2 |

|

|

6 |

|

|

0.6 |

2.2 |

3 |

|

|

8 |

|

|

|

1 |

1.5 |

|

|

Copper plate |

1 |

9 |

18 |

25 |

28 |

30 |

|

2 |

3 |

6 |

8 |

15 |

17 |

|

|

3 |

0.6 |

1.8 |

2.4 |

3.6 |

12 |

|

|

4 |

|

0.6 |

0.9 |

1.5 |

8 |

|

|

5 |

|

|

0.8 |

3.2 |

5 |

|

|

6 |

|

|

0.6 |

2.2 |

3 |

Technical parameter

|

1 |

Model |

ER3015-2000W |

|

2 |

Cutting working area |

3000x1500mm |

|

3 |

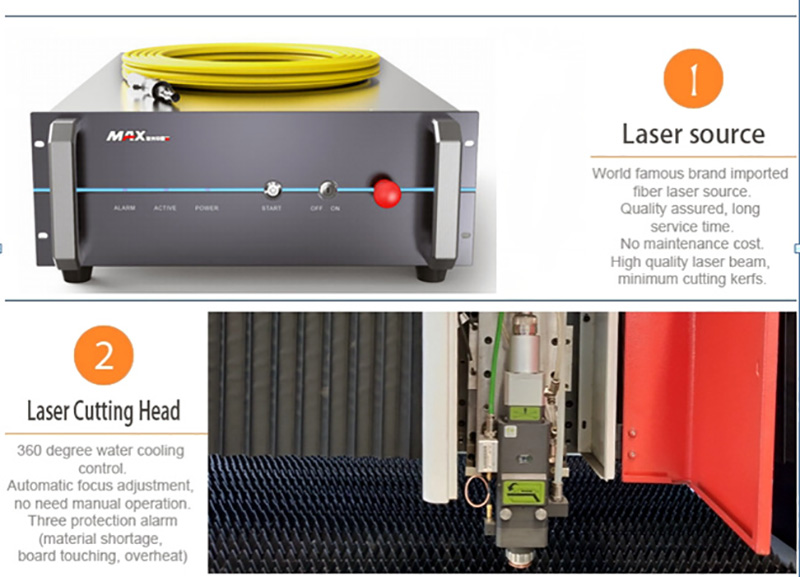

Laser Generator |

MAX |

|

4 |

Cooling mode |

Water cooling and protection system |

|

5 |

Transmission system |

Gear + rails |

|

6 |

Fiber Laser Power |

2000W |

|

7 |

X.Y axis location accuracy |

±0.02mm |

|

8 |

X.Y axis repeat location accuracy |

±0.02mm |

|

9 |

X.Y axis max moving speed |

120m/min |

|

10 |

Max Acceleration |

1.5G |

|

11 |

Driver system power |

Y=1500W; X1=1000W; X2=1000W; Z=400W |

|

12 |

Laser wave length |

2080nm |

|

13 |

Machine color |

Support custom made |

|

14 |

Gross weight |

4500KG |

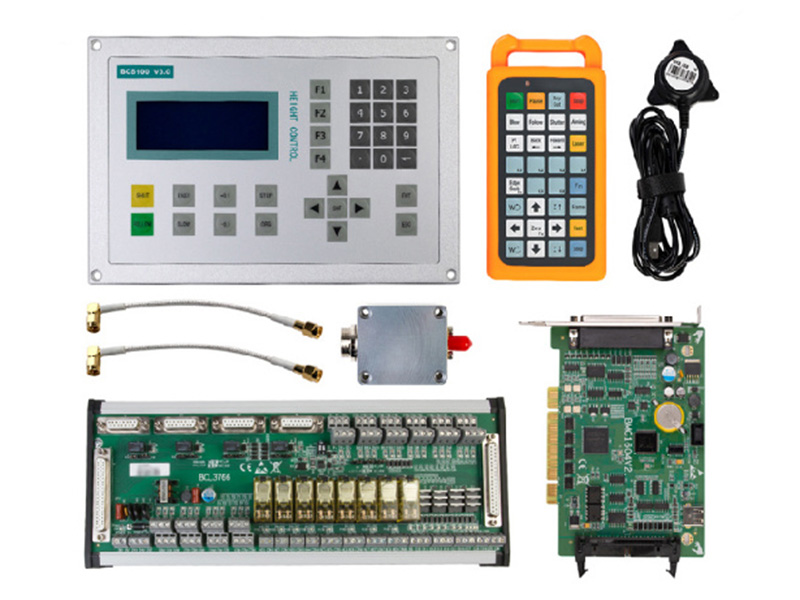

Accessories brand list

|

No. |

Name |

Manufacturer |

Configuration |

|

1 |

CNC Controller |

CYPONE |

Standard |

|

2 |

Servo Motor |

YASKAWA |

|

|

3 |

Servo Driver |

YASKAWA |

|

|

4 |

Linear Guide Rail |

HIWIN |

|

|

5 |

Laser Generator |

MAX |

|

|

6 |

CAD/CAM SOFTWARE / SOFTWARE CAD / CAM |

CYPCUT 1000 |

|

|

7 |

Cutting Torch |

RAYTOOLS |

|

|

8 |

Reducer |

SHIMPO |

|

|

9 |

Rack |

YYC |

|

|

10 |

Cutting Gas Control System |

SMC |

|

|

11 |

Water Cooling System |

HANLI |

|

|

12 |

Network connection from external |

ERMAK |

|

|

13 |

Effective high to low pressure gas exchange system |

ERMAK |

|

|

14 |

Capacitive Sensor, high pressure cutting head |

ERMAK |

|

|

15 |

Automatic mechanized Nesting power output controller |

ERMAK |

|

|

16 |

Automatic time and unit cost calculation function |

ERMAK |

|

|

17 |

Smoke extraction |

ERMAK |

|

|

18 |

Gas pressures and special system for high pressure cutting. |

ERMAK |

|

|

19 |

Laser Generator |

RAYCUS,IPG |

Option Part |

|

20 |

CNC Controller |

CYPCUT 2000 |

|

|

21 |

Cutting head Auto Focus |

RAYTOOLS BM110 |

|

|

22 |

Cutting Torch |

WXS,PRECITEC |

|

|

23 |

Automatic table exchanger |

ERMAK |

|

|

24 |

Pipe cutting Device |

ERMAK |

|

|

25 |

Air Compressor |

ERMAK |

|

|

26 |

Cover |

ERMAK |

|

|

27 |

Segmented smoke exhaust system |

ERMAK |

|

|

28 |

Machine Table Slat Cleaner |

ERMAK |

|

|

29 |

Anti-collision system |

CYPCUT |

SPARE PARTS AND SPECIAL TOOLS

|

Accessory |

||||

|

1 |

GB801-2011 |

Bolt M16X500 |

Piece |

4 |

|

2 |

GB7160-2016 |

Nuts M16 |

Piece |

4 |

|

3 |

GB610-2014 |

Electrical box key |

Piece |

1 |

|

4 |

GB766-2018 |

Button box power key |

Piece |

2 |

|

Spare parts |

||||

|

5 |

GB98-2015 |

Lens |

Piece |

10 |

|

6 |

GB638-2018 |

Nozzle |

Piece |

10 |

LIST OF ACCOMPANYING DOCUMENTS:

|

Document |

|||

|

1 |

Manual Operation Book |

Copy |

1 |

|

2 |

Certification of CE |

Copy |

1 |

|

3 |

Packing list/Commercial Invoice ( Certification of Origin) |

Copy |

1 |

|

4 |

Inspection Qualified |

Copy |

1 |

OPITION PART

1.Laser Generator

-

Raycus

-

IPG

2.CYPCUT 2000

3.Cutting Torch

-

BM110

-

WSX

-

Precitec

4.Automatic table exchanger

5.Pipe cutting Device

6.AIR COMPRESSOR

- 7.Cover

- 8.Segmented Smoke Exhaust System

- 9.Machine Table Slat Cleaner

- 10.Anti-collision system

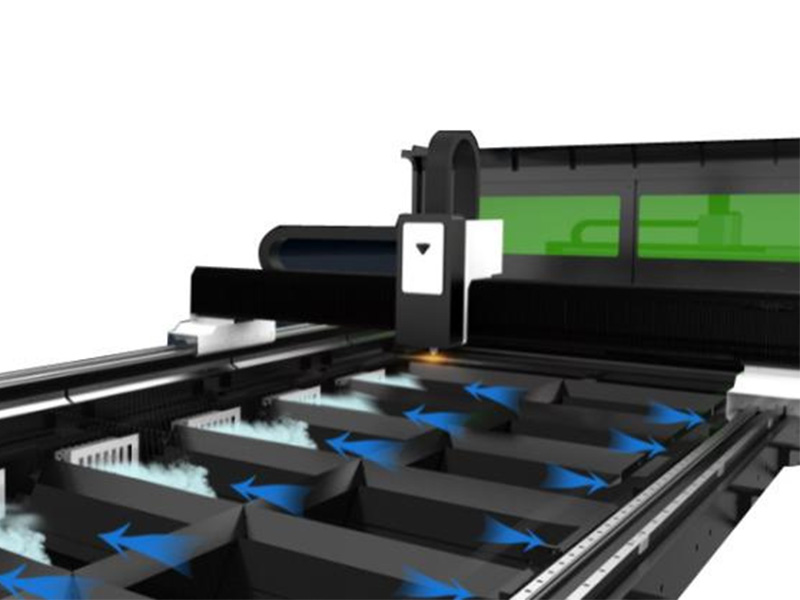

PRODUCTS DETAILS

PRODUCTS DISPLAY

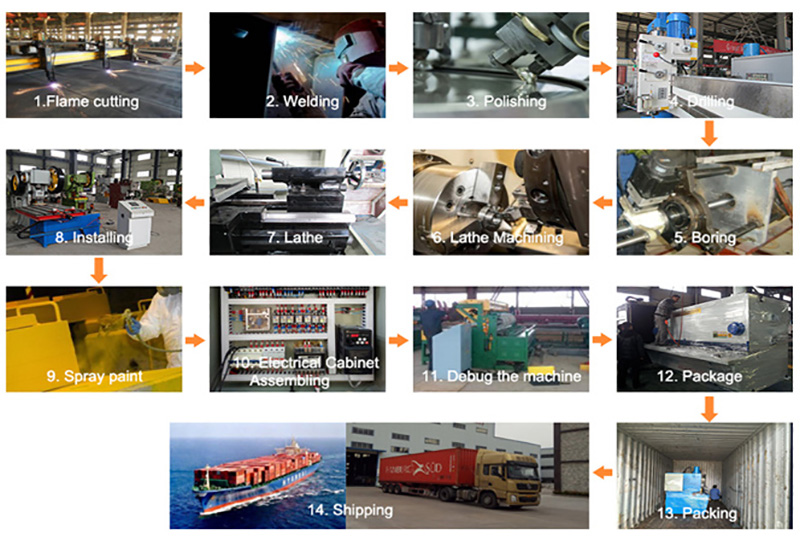

PRODUCTION FLOW

SHIPPING

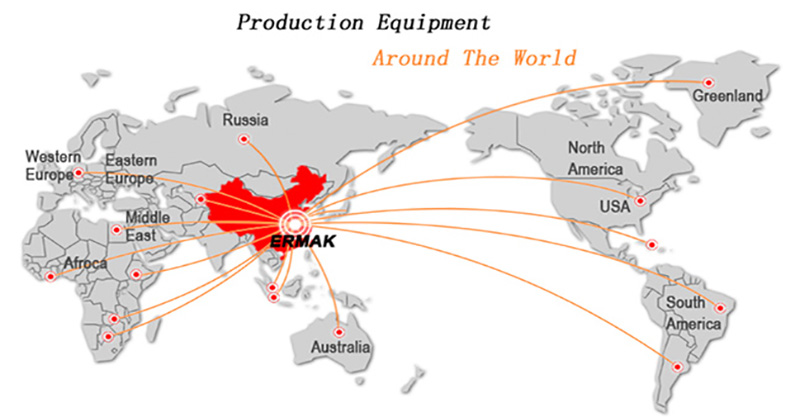

GLOBAL COOPERATION